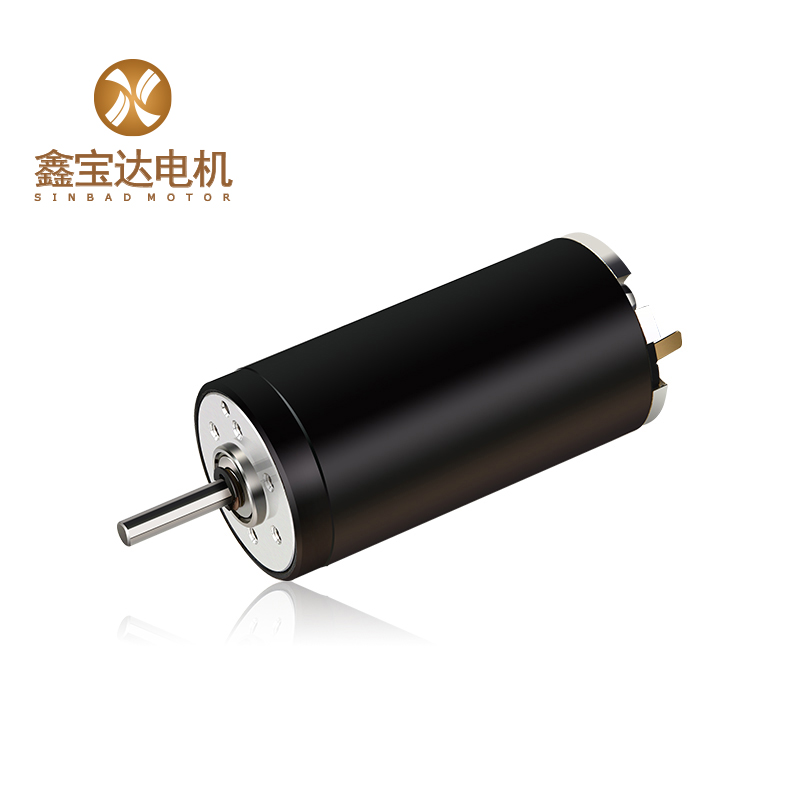

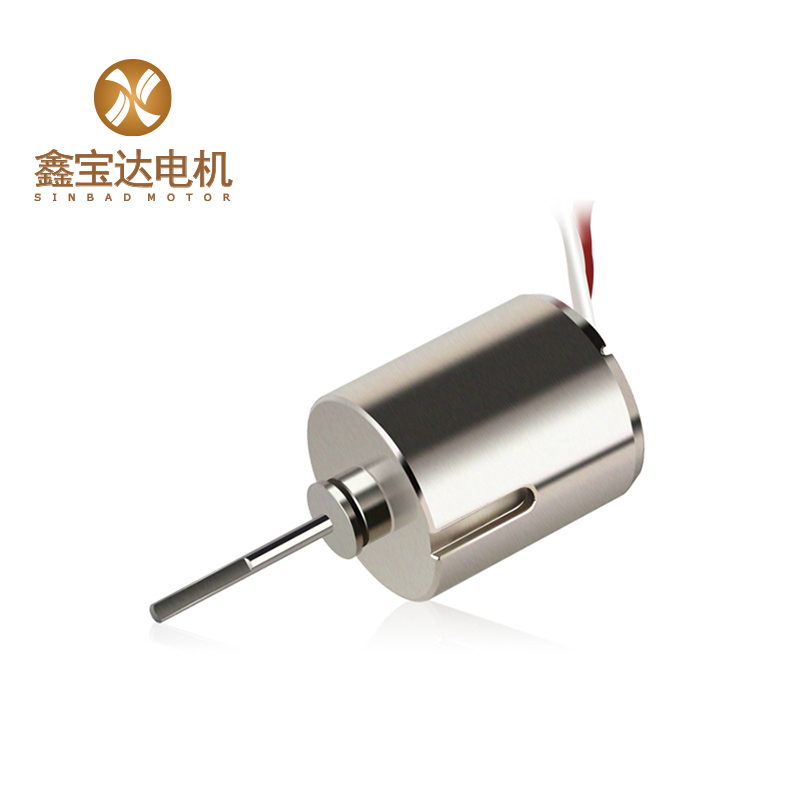

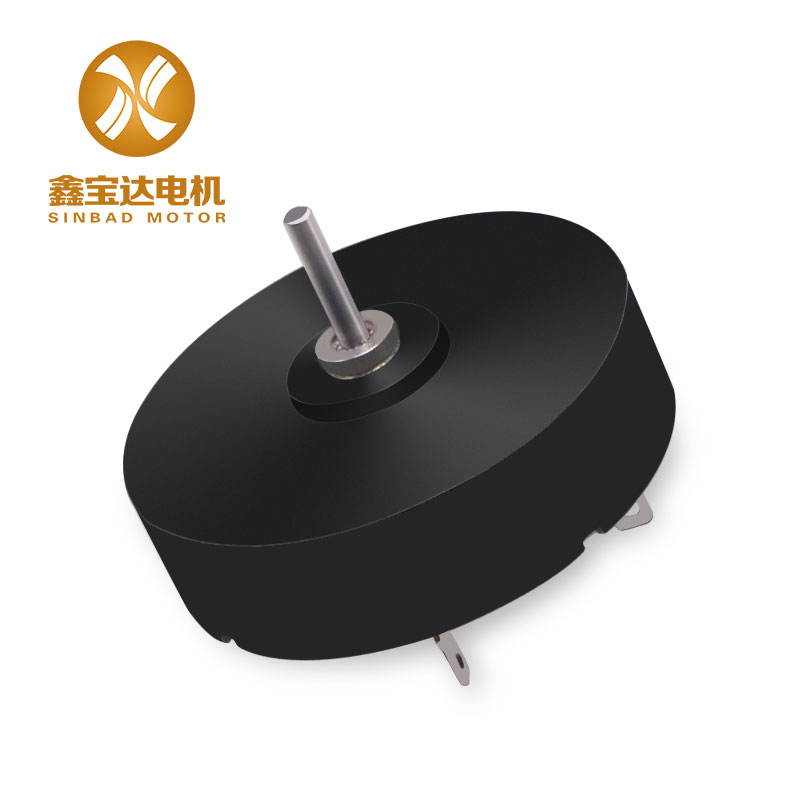

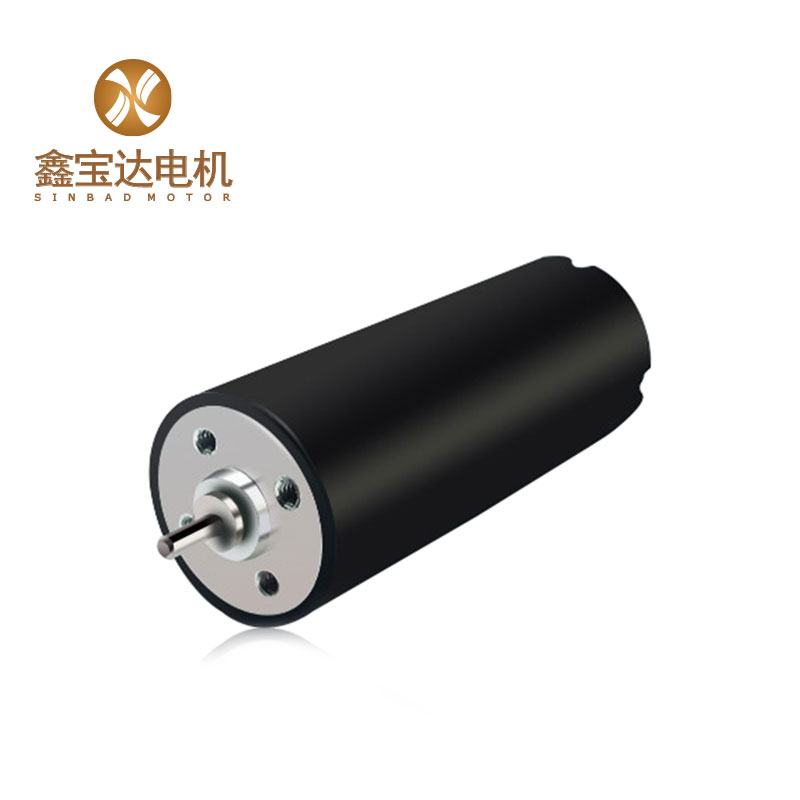

High speed XBD-2431 precious metal brushed motor coreless micro dc motor

Product Introduction

The XBD-2431 precious metal motors have advantages in some special environments. Since precious metal materials have good corrosion resistance, precious metal motors can maintain good performance and have strong adaptability in some special environments, such as high temperature, high humidity, corrosive gas environments, etc.

With the continuous development of science and technology, people’s requirements for motor performance continue to increase, and the application prospects of precious metal motors are also constantly expanding. For example, with the rapid development of new energy vehicles, aerospace and other fields, the requirements for motor performance are getting higher and higher. Our Sinbad precious metal motors have broad application prospects in these fields.

Features

1.Excellent electrical conductivity: Precious metals such as silver, platinum, gold, etc. have excellent electrical conductivity, which can effectively reduce the resistance between the brush and the armature and improve the efficiency of the motor.

2.Strong wear resistance: Precious metal materials have high hardness and wear resistance, which can reduce the wear between the brush and armature and extend the service life of the motor.

3.Good corrosion resistance: Precious metal materials have good corrosion resistance and can maintain stable performance in harsh environments, making them suitable for some special working environments.

4.Low contact resistance: The contact resistance between the precious metal brush and the armature is low, which is beneficial to reducing energy loss and improving the efficiency of the motor.

5.High thermal conductivity: Precious metals have high thermal conductivity and can effectively dissipate heat, which is beneficial to the stable operation of the motor for a long time.

6.Adapt to high-temperature environments: Precious metal materials can maintain stable performance in high-temperature environments and are suitable for high-temperature working environments.

7.Excellent electrochemical stability: Noble metal materials have good electrochemical stability and can maintain stable performance in electrochemical corrosion environments.

8.Low friction coefficient: The friction coefficient between the precious metal brush and the armature is low, which is beneficial to reducing energy loss and improving the efficiency of the motor.

Application

Sinbad coreless motor have a wide range of application such as robots, drones, medical equipment, automobiles, information and communications, power tools, beauty equipment, precision instruments and military industry.

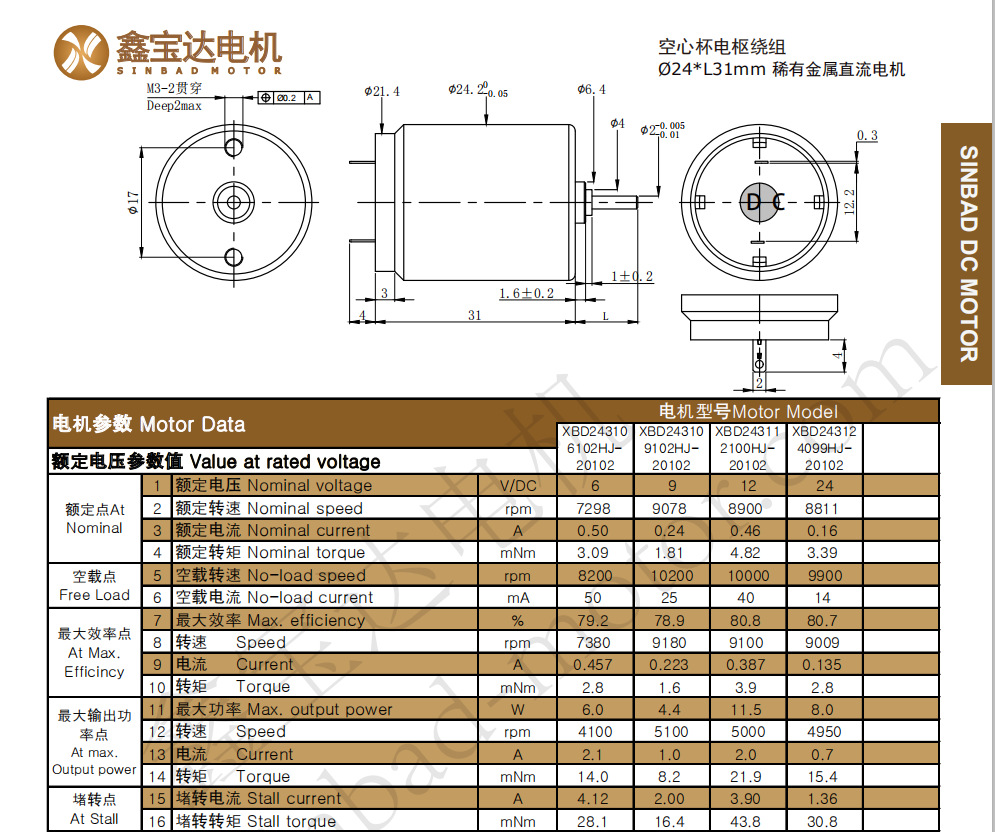

Parameters

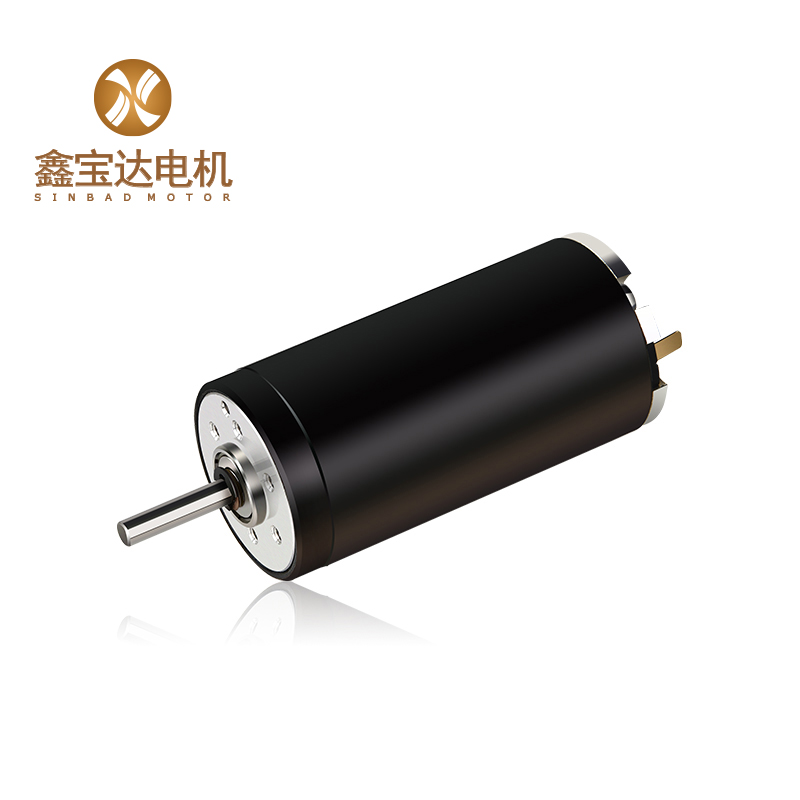

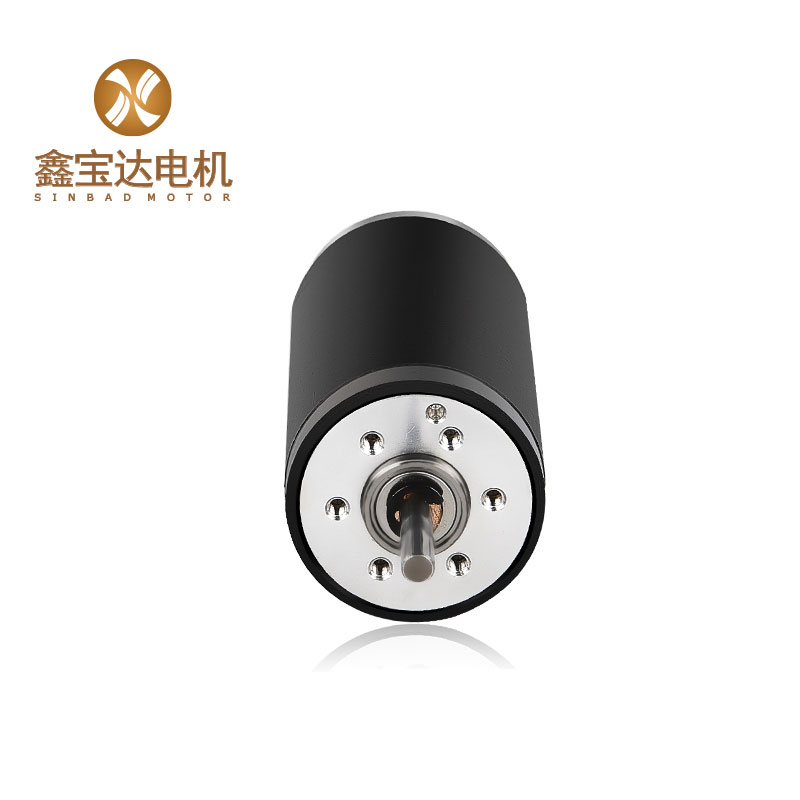

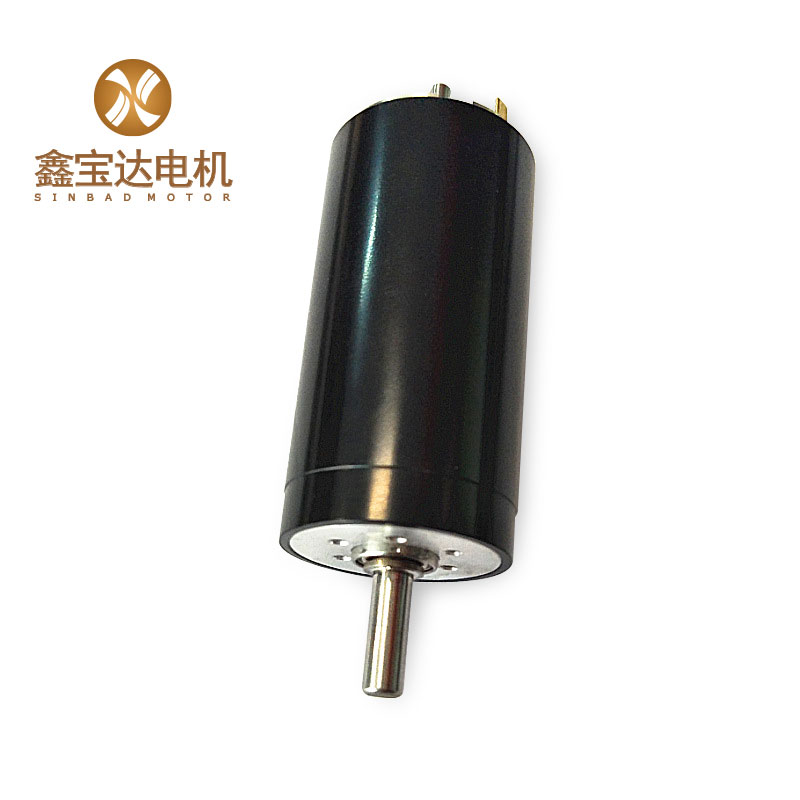

Samples

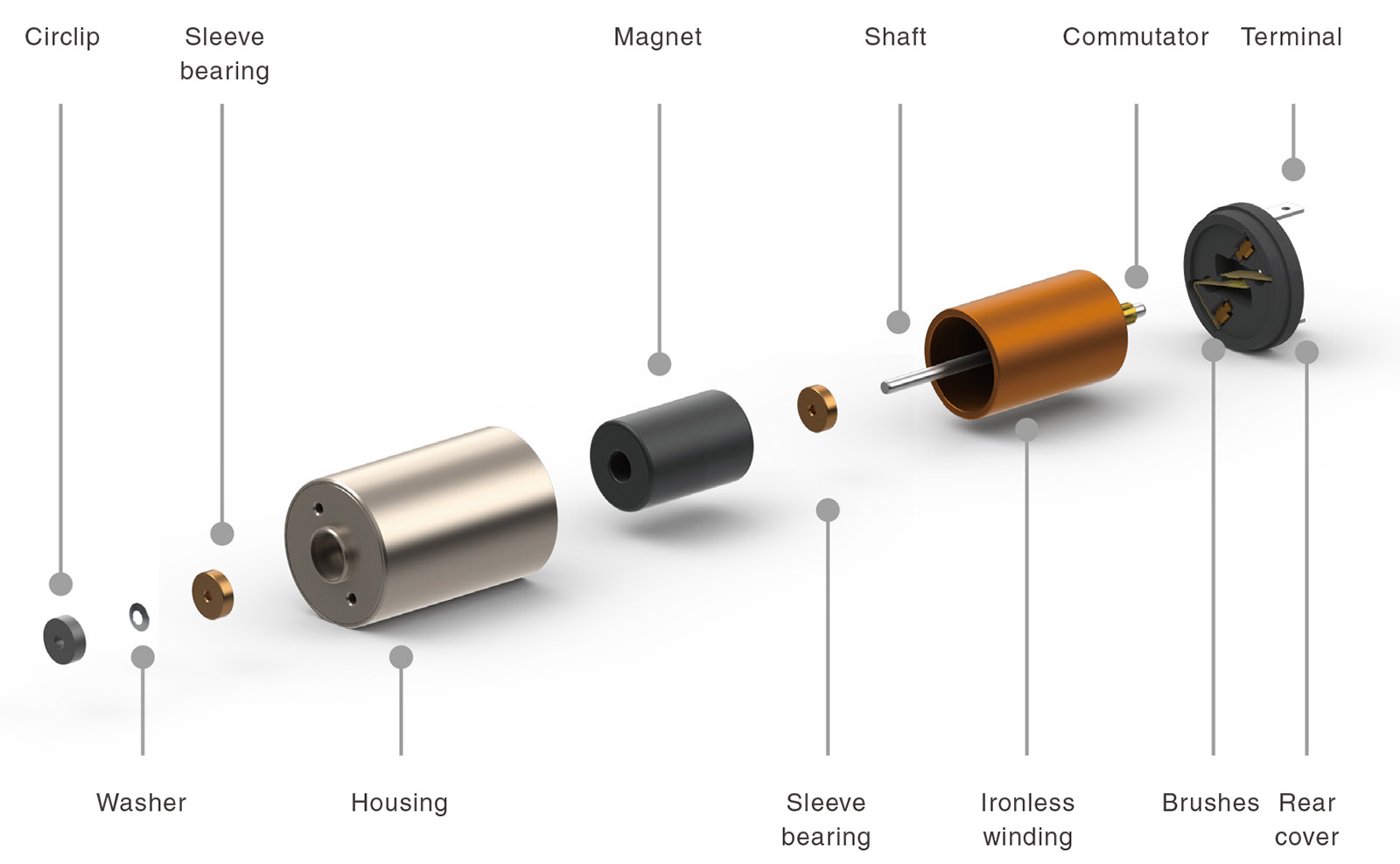

Structures

FAQ

We are the SGS authorized manufacturer, and all our items is CE, FCC, RoHS certified.

Yes, we accept OEM and ODM,we can change logo and parameter if you need. It would take 5-7

working days with customized logo

It takes 10 working days for 1-5Opcs, for mass production, the lead time is 24 working days.

DHL, Fedex, TNT, UPS, EMS, By Air, By Sea, customer forwarder acceptable.

We accept L/C, T/T, Alibaba Trade Assurance, Paypal etc.

6.1. If the item is defect when you receive it or you are not satisfied with it, please return it within 14 days for a replacement or money back. But the items must be back in factory condition.

Please contact us in advance and double check the return address before you return it.

6.2. If item is defective in 3 months, we could send you a new replacement for free or offer full refund. after we receive the defective item

6.3. If item is defective in 12 months, we could also offer you replacement service, but you have to pay for the extra shipping expenses.

We have 6 years experienced QC to strictly check the appearance and function one by one to promise the defective rate within international standard.