We live in an era of high-intensity and high-frequency vehicles, and the safe tire pressure of automobile tires becomes particularly important. Stable tire pressure can:

1. Effective security

2. Extend tire life

3. Protect the suspension system

4. Reduce fuel consumption

5. Improve ride comfort

Therefore, more and more people will be equipped with a car air pump, to keep the tire pressure in the normal range, when and where can effectively protect the travel.

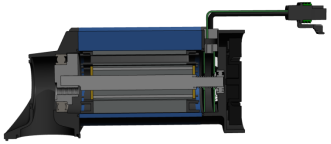

A car air pump is a common car accessory used to inflate car tires. The coreless motor is the core component of the air pump. It compresses and delivers air to the tire through rotation. When designing and manufacturing coreless motors for vehicle air pumps, many factors need to be considered, including power, efficiency, noise, life, and cost. A solution to meet these requirements is described below.

First of all, the power and efficiency of the coreless motor are key considerations. In order to improve power and efficiency, a high-performance permanent magnet DC motor can be used as the driving source of the coreless motor. This kind of motor has high speed, high efficiency and small size, and can provide enough power to drive the air pump. In addition, advanced motor control technologies, such as PWM speed control and motor drivers, can be used to improve the motor’s response speed and control accuracy, thereby further improving overall efficiency.

Secondly, noise is another important factor to consider. In order to reduce the noise level of coreless motors, low-noise designed motors and shock-absorbing materials can be used. In addition, by optimizing the structural design and vibration reduction measures of the coreless motor, the transmission of vibration and noise can be effectively reduced and the user experience improved.

Third, the life of the coreless motor is also an important factor to consider. In order to increase the life of the coreless motor, high-quality bearings and seals can be used to reduce friction and wear. In addition, regular maintenance and upkeep are also the key to extending the life of the coreless motor. Instructions and maintenance suggestions can be provided to help users use and maintain the air pump correctly.

Finally, cost is one of the important factors to consider when designing a car air pump coreless motor. In order to reduce costs, mature production processes and automated production lines can be used to improve production efficiency and reduce production costs. In addition, suitable material and component suppliers can be selected to reduce the procurement cost of raw materials and components.

To sum up, the design and manufacture of coreless motors for vehicle air pumps requires comprehensive consideration of multiple factors such as power, efficiency, noise, lifespan and cost. By using high-performance permanent magnet DC motors, advanced motor control technology, low-noise design and high-quality components, high-performance, low-noise, long-life and low-cost solutions for coreless motors can be achieved. Such a design solution will be able to meet users’ needs for efficient, reliable and comfortable use of vehicle air pumps.

Writer: Sharon

Post time: Aug-06-2024