Electric claws are used in industrial manufacturing and automated production, characterized by excellent gripping force and high controllability, and have been widely applied in fields such as robots, automated assembly lines, and CNC machines. In practical use, due to the diversity of product specifications and the continuous improvement of automation demands, the adoption of electric claws in conjunction with servo drivers can enhance the flexibility of the production line in handling basic tasks related to parts. As one of the important components of modern industrial automation, in the future development trend, electric claws will play a more important role in the production process. Especially with the continuous construction and development of smart factories, this technology will be applied more deeply and comprehensively, greatly improving product quality and precision.

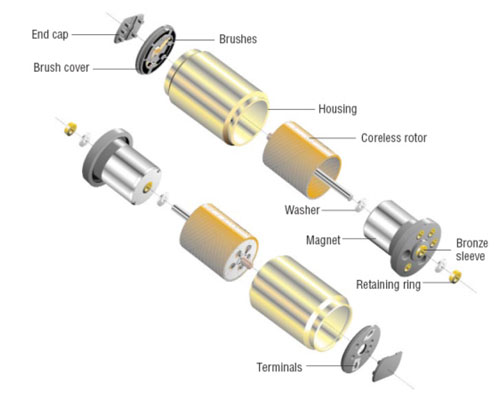

An electric claw is a terminal tool of a mechanical arm that achieves the action of gripping and releasing objects through electric control. It can achieve efficient, fast, and accurate material grasping and placement operations, improving production efficiency and quality. The claw consists of a motor, reducer, transmission system, and claw itself. Among them, the motor is the core component of the electric claw, providing the power source. By controlling the motor's speed and direction, various actions such as opening and closing, rotation of the claw can be realized.

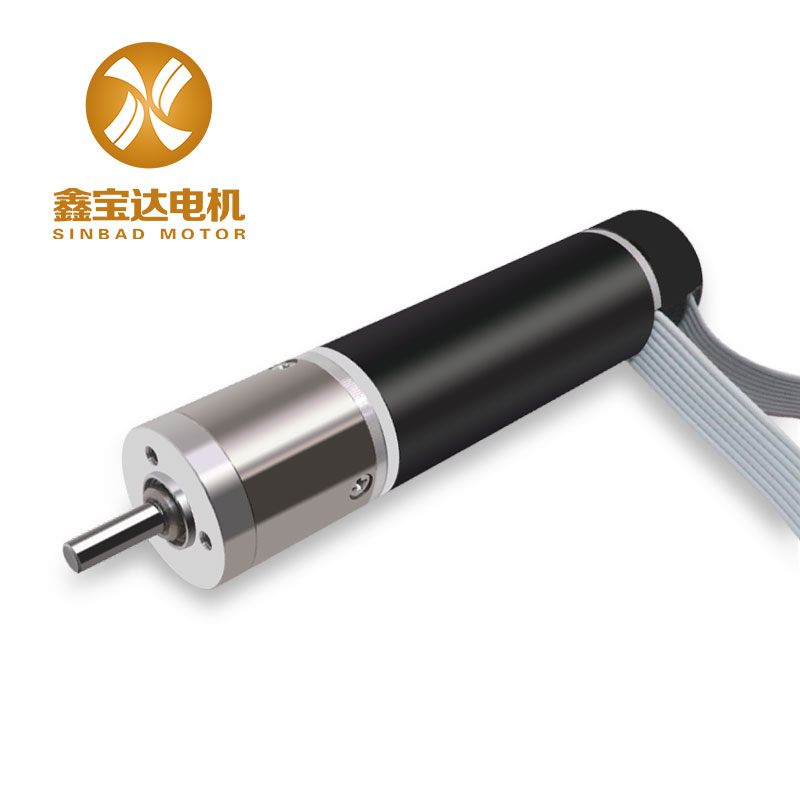

Sinbad Motor, based on more than 10 years of experience in motor research and manufacturing, combined with drive gear box design, simulation analysis, noise analysis, and other technical means, has proposed a solution for the electric claw drive system. This solution uses 22mm and 24mm hollow cup motors as the power source, with planetary reduction gears to increase force, and is equipped with drivers and high-resolution sensors, giving the electric claw the following characteristics:

- High-precision control: The coreless motor used in the electric claw has high-precision position control and force control capabilities, allowing for adjustment of the gripping force and position as needed.

- High-speed response: The hollow cup motor used in the electric claw has a very fast response speed, enabling rapid gripping and releasing operations, thereby improving production efficiency.

- Programmable control: The electric claw motor is programmable, allowing for the setting of different gripping forces and positions according to different working scenarios.

- Low energy consumption: The electric claw uses efficient hollow cup motors and electronic control technology, which can save energy and reduce production costs.

Writer

Ziana

Post time: Jun-19-2024