Main features of coreless motor:

1. Energy-saving features: The energy conversion efficiency is very high, and its maximum efficiency is generally above 70%, and some products can reach above 90% (the iron core motor is generally 70%).

2. Control characteristics: fast starting and braking, extremely fast response, mechanical time constant less than 28 milliseconds, some products can reach within 10 milliseconds (iron core motors are generally above 100 milliseconds); under high-speed operation in the recommended operating area , It is convenient to adjust the speed sensitively.

3. Drag characteristics: the operation stability is very reliable, and the fluctuation of the speed is very small. As a micro motor, the fluctuation of the speed can be easily controlled within 2%.

In addition, the energy density of the coreless motor is greatly improved, and compared with the iron core motor of the same power, its weight and volume are reduced by 1/3-1/2.

In order to let the majority of users have a better understanding of the coreless brushless motor, the following will discuss the main related fields of its main application.

Application field 1: electronic digital or office computer peripheral equipment

In the application range of coreless brushless motors, office computers, peripheral equipment and electronic digital are the most numerous application fields, especially in daily life, such as: movie cameras, fax machines, printers, copiers, drives, etc.

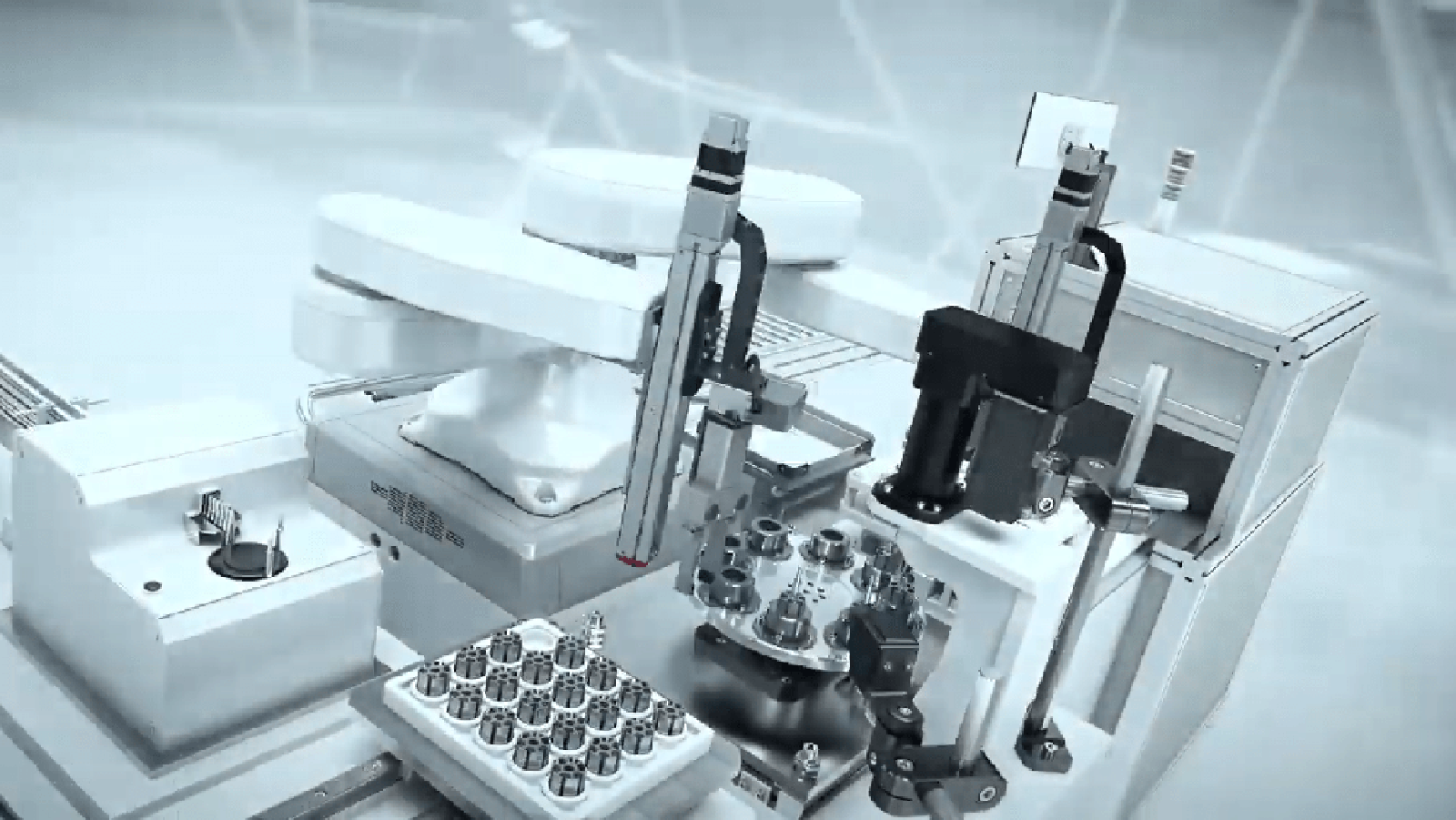

Application field 2: industrial control field

With the large-scale production and research and development of coreless brushless motors, its technology has become mature, and the drive system made of it has become more and more widely used in industrial production, and it can even become the first choice for industrial electric motors. mainstream. In order to reduce costs and improve operating efficiency in the industry, major manufacturers need to provide different types of motors to meet the needs of different systems. Therefore, coreless brushless motors are more and more involved in the industry, and now they have involved Printing, metallurgy, automated production lines, textiles and CNC machine tools and other industries.

Application field 3: test equipment field

As we all know, doing experiments also requires a lot of experimental equipment, and the components of these experimental equipment include coreless brushless motors. This is because the equipment used in the laboratory has very high requirements on the motor, not only requires good controllability, but also requires very high precision, such as mixers, centrifuges, etc., because the equipment made of coreless brushless motors can run stably , flexible loading and unloading, and no noise, so its application in the experimental field is becoming more and more extensive.

Application field 4: home appliances and other fields

We use many household appliances in our daily life, such as inverter refrigerators and inverter air conditioners. These common frequency conversion devices are actually mainly due to the superior performance of coreless brushless motors. The frequency conversion technology it uses is actually the transition from induction motors to unparalleled motors and controllers for household motors, so it can meet the requirements of high comfort, intelligence, low noise, energy saving and environmental protection.

Application field 5: precision instruments requiring fast response

Because the coreless motor gets rid of the limitation of slow speed regulation of the iron core, the sensitivity of its speed start and speed adjustment is extremely high. In the military field, it can shorten the response time of high-magnification optical drives and improve the hit rate of missiles; in the field of scientific research, it can enable various instruments for collecting data to have automatic fast focusing, high-sensitivity recording and analysis capabilities that were not available before.

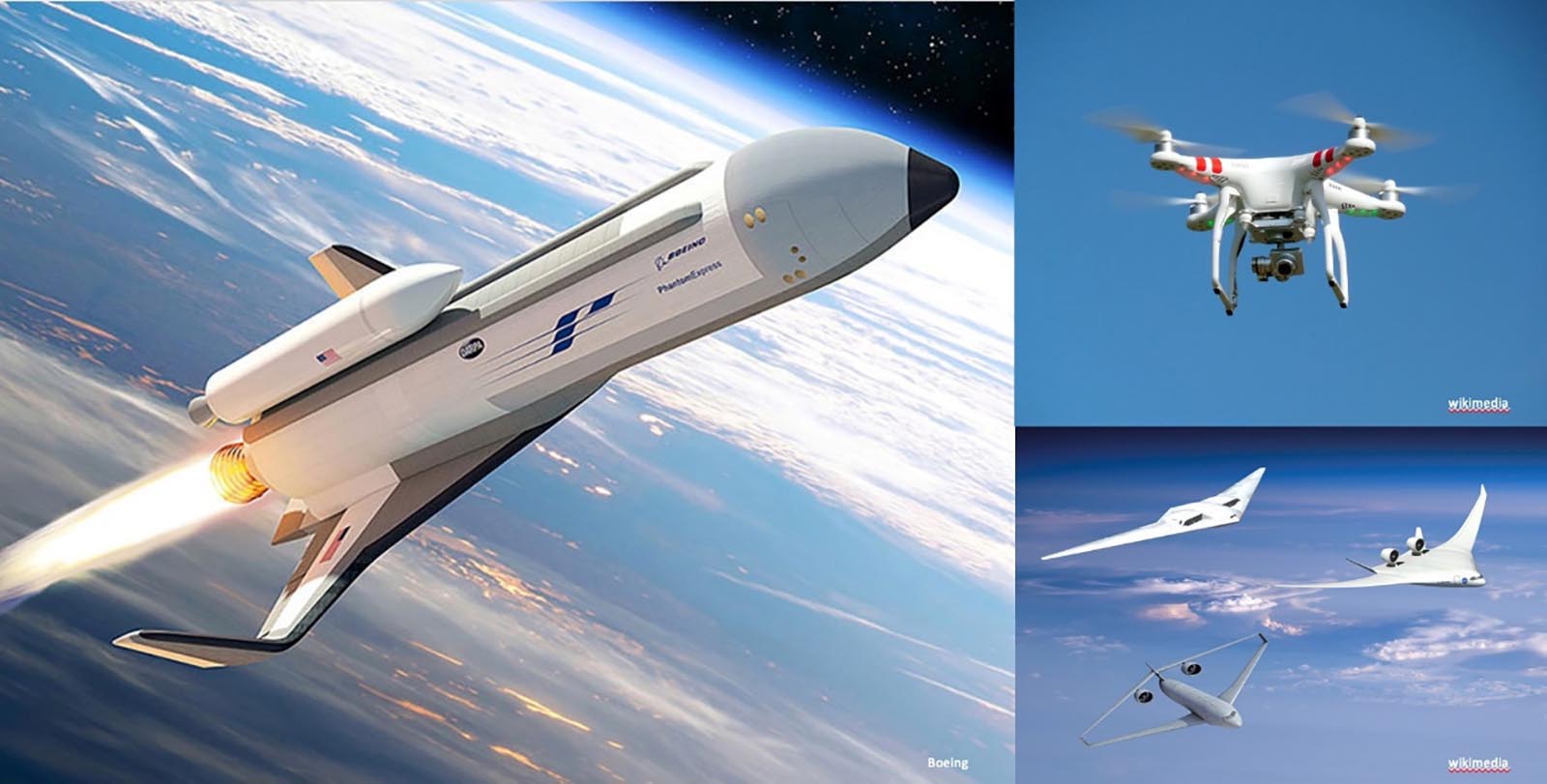

Application field 6: various aerospace vehicles

Since the coreless motor gets rid of the restrictions on the weight and design space of the iron core, it not only occupies a small space, but also can fine-tune the structure according to the requirements of various aerospace vehicles, ranging from military precision UAV motors to small Coreless motors can be seen in common aerospace model generators in daily life.

Application field 7: require the use of convenient precision instruments

Due to the high-efficiency energy conversion rate, small size, light weight, and strong endurance of the coreless motor, it is very suitable for use in various precision instruments that require easy use, such as metal detectors, personal navigators, field Engineering instruments for work.

Post time: Mar-18-2023