In order for the brushless DC motor to operate stably, the following points must be achieved:

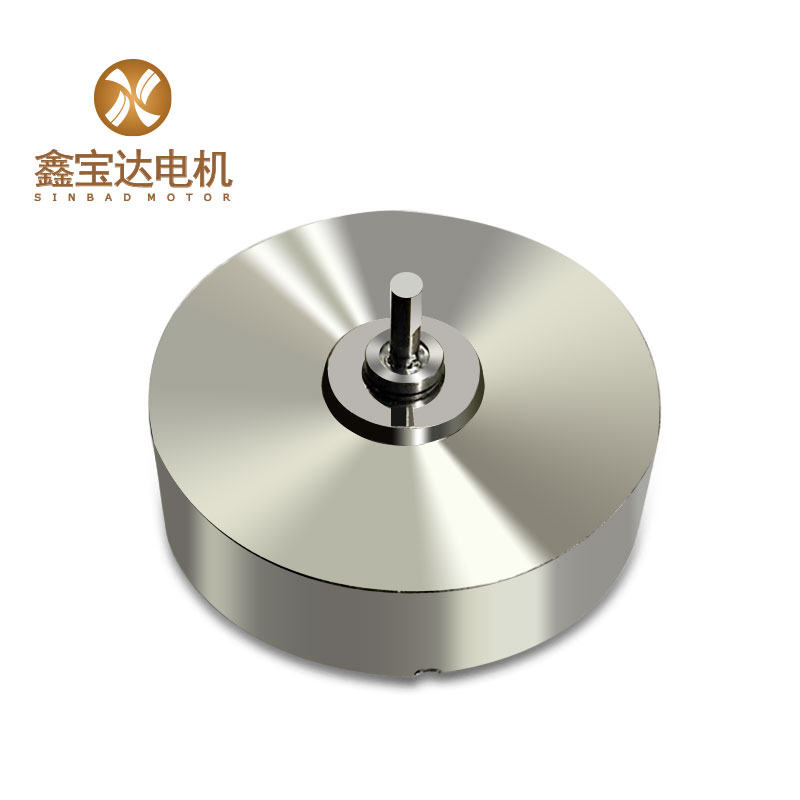

1. The accuracy of the bearings must meet the requirements, and original NSK bearings imported from Japan must be used.

2. The stator winding curve of the brushless DC motor must be based on the data requirements. More or less will affect the motor torque.

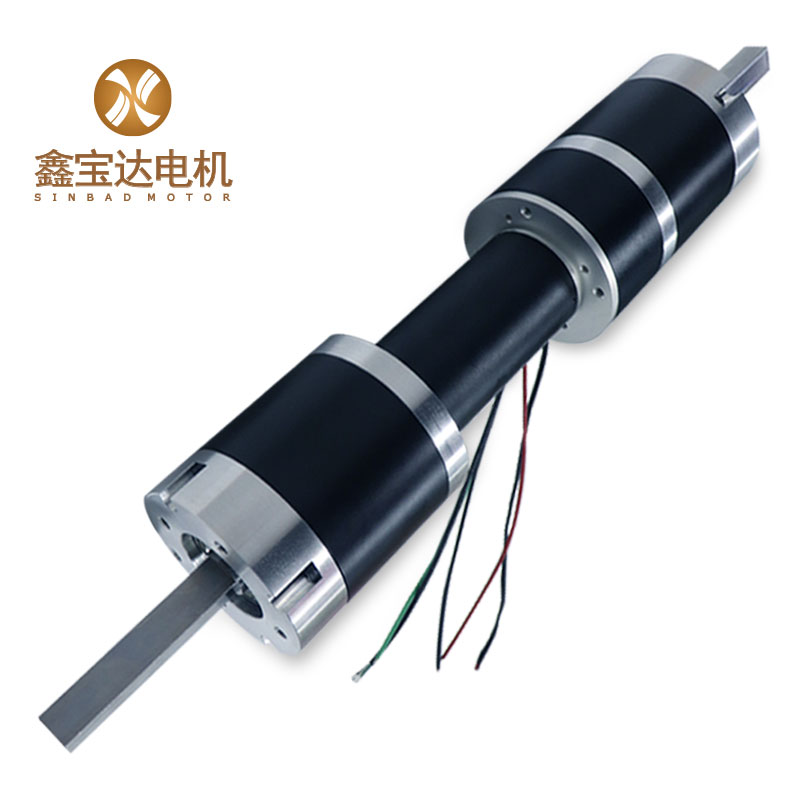

3. The brushless DC motor rotor shaft requires high precision, which may not be achieved by manual gear hobbing using a CNC gear hobbing machine.

4. The burrs on the DC motor stator must be removed; it may not be removed by blowing with a gun, but can be removed with glue.

5. The use of sensors can accurately record the angular position and the rotor angle of the brushless DC motor. The accuracy of accurate measurement can reduce the torque vibration of the brushless DC motor during operation, making the operation of the brushless DC motor faster. More stable, while the energy conversion efficiency is higher.

6. The protection level of the brushless DC motor must be such that when the DC motor rotates without power, the current generated will not penetrate the copper wire and drive.

Post time: May-20-2024