A gas nail gun is a tool commonly used in industries such as construction, carpentry and furniture manufacturing. It uses gas to push nails or screws to fasten materials quickly and efficiently. The coreless motor is one of the core components of the gas nail gun. It is responsible for converting gas into power to drive nails. When selecting a coreless motor, multiple factors need to be considered, including power, efficiency, reliability, cost, etc. The following will start from these aspects and conduct a detailed analysis of the coreless cup motor selection of the gas nail gun.

First of all, power is one of the important considerations in coreless motor selection. Gas nail guns need to have enough power to ensure that they can drive nails quickly and stably on a variety of materials. Therefore, when selecting a model, you need to determine the required power range based on the usage scenarios and needs of the gas nail gun, and then select the corresponding coreless motor model.

Secondly, efficiency is also a key consideration in coreless motor selection. The efficient coreless motor can effectively convert gas energy into mechanical power, improve the working efficiency of gas nail guns and reduce energy consumption. Therefore, it is necessary to choose a coreless motor with high efficiency when selecting a model to improve the overall performance of the gas nail gun.

In addition, reliability is also one of the important considerations in coreless motor selection. Gas nail guns usually need to be used in harsh construction environments, so the coreless motor needs to have good durability and stability, and can run stably for a long time without being affected by the external environment. When selecting a model, you need to choose a coreless motor with high reliability to ensure the stable operation of the gas nail gun.

In addition, cost is also one of the considerations in coreless motor selection. When selecting, you need to comprehensively consider the price, performance, reliability and other factors of the coreless motor, and choose a product with a higher price ratio to ensure that the cost is reduced as much as possible while meeting the needs.

In summary, the selection of coreless motors for gas nail guns requires comprehensive consideration of factors such as power, efficiency, reliability, and cost to select a suitable product. Through reasonable selection, the working efficiency and stability of the gas nail gun can be improved to meet the use needs in different scenarios.

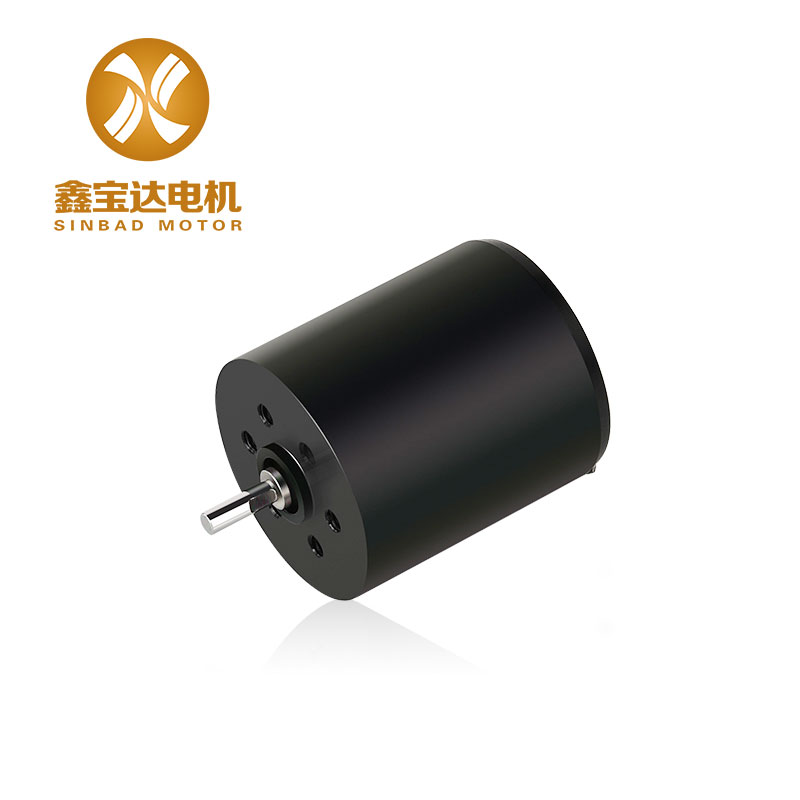

Since our company Sinbad have had many successful use cases on the product of gas nail gun, we recommend this carbon brush 2225 motor for the product , which will be a perfect solution.

Writer : Sharon

Post time: Jul-30-2024