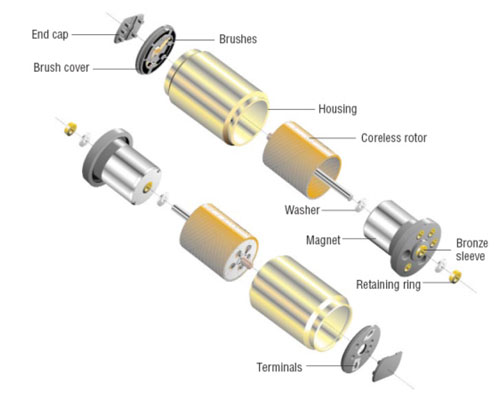

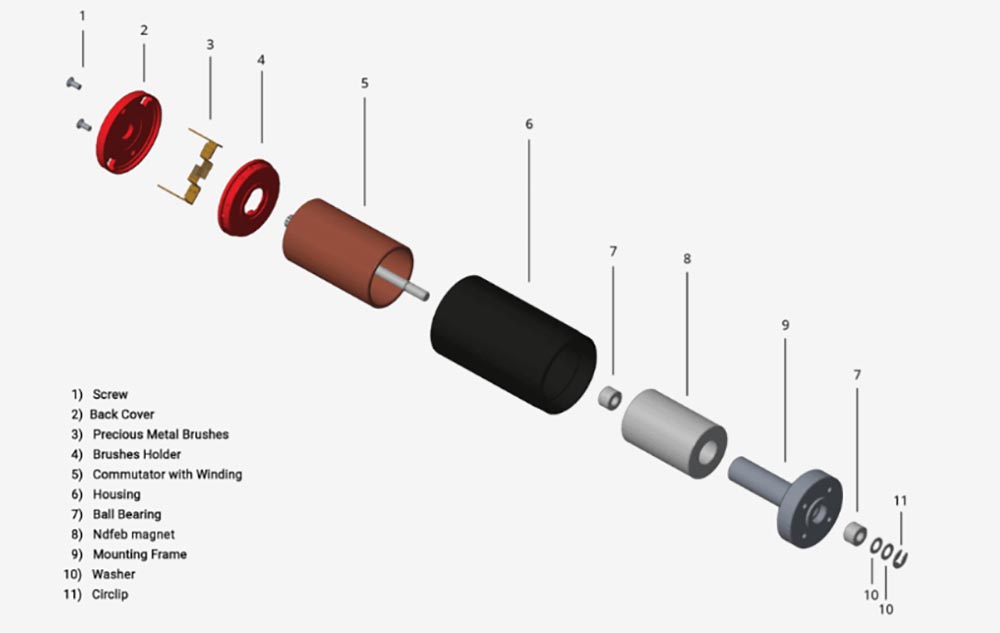

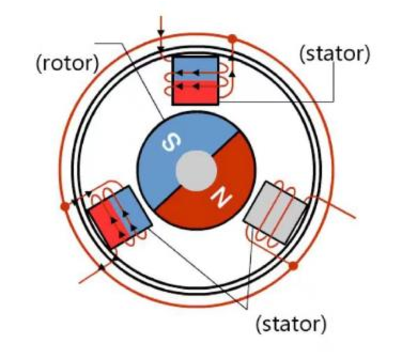

The difference between brushless motor and carbon brush motor:

1. Scope of application:

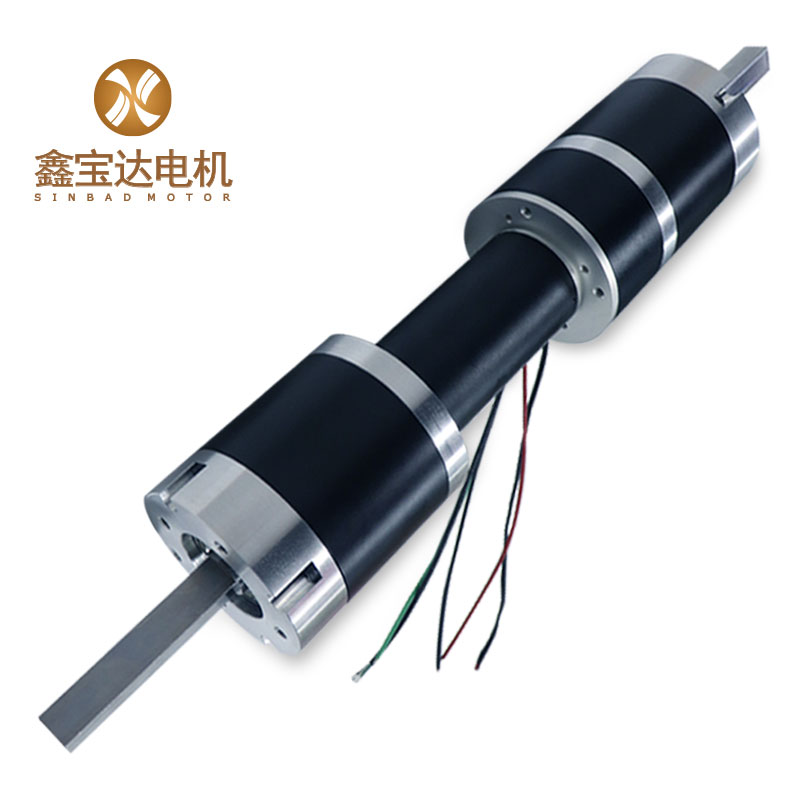

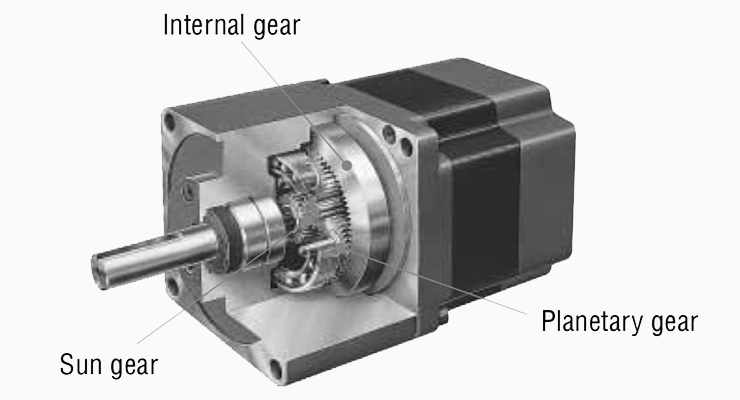

Brushless motors: usually used on equipment with relatively high control requirements and high speeds, such as model aircraft, precision instruments and other equipment that have strict motor speed control and high speeds.

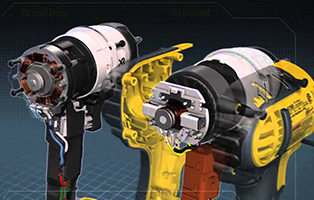

Carbon brush motor: Usually power equipment uses brush motors, such as hair dryers, factory motors, household range hoods, etc. In addition, the speed of series motors can also reach very high speeds. However, due to the wear of the carbon brushes, the use The lifespan is not as good as brushless motors.

2. Service life:

Brushless motor: Usually the service life is on the order of tens of thousands of hours, but the service life of brushless motors also varies greatly due to different bearings.

Carbon brush motor: Usually the continuous working life of a brush motor ranges from a few hundred to more than 1,000 hours. When the use limit is reached, the carbon brush needs to be replaced, otherwise it will easily cause bearing wear.

3. Effect of use:

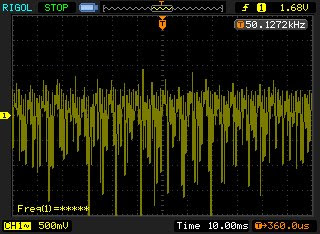

Brushless motor: Usually digital frequency control, with strong controllability, it can be easily realized from a few revolutions per minute to tens of thousands of revolutions per minute.

Carbon brush motor: The old carbon brush motor generally has a constant working speed after starting, and it is not easy to adjust the speed. The series motor can also reach 20,000 rpm, but its service life will be relatively short.

4. Energy saving:

Relatively speaking, brushless motors controlled by variable frequency technology will save much more energy than series motors. The most typical ones are variable frequency air conditioners and refrigerators.

5. In terms of future maintenance, carbon brush motors need to replace the carbon brushes. If the replacement is not timely, it will cause damage to the motor. Brushless motors have a long service life, usually more than 10 times that of brushed motors. However, if they are broken, they need to be replaced. Motor, but daily maintenance is basically unnecessary.

6. The noise aspect has nothing to do with whether it is a brushed motor or not. It mainly depends on the coordination between the bearings and the internal components of the motor.

7. The parameter indicators of the model brushless motor, in addition to the dimensions (outer diameter, length, shaft diameter, etc.), weight, voltage range, no-load current, maximum current and other parameters, there is also an important indicator - KV value. This The numerical value is a unique performance parameter of the brushless motor and an important data for judging the performance characteristics of the brushless motor.

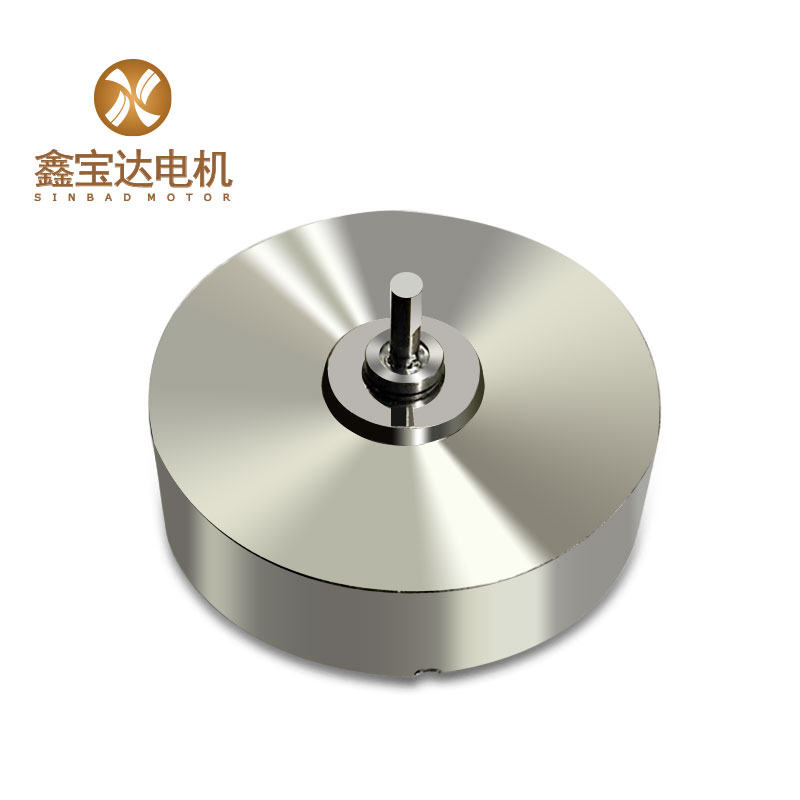

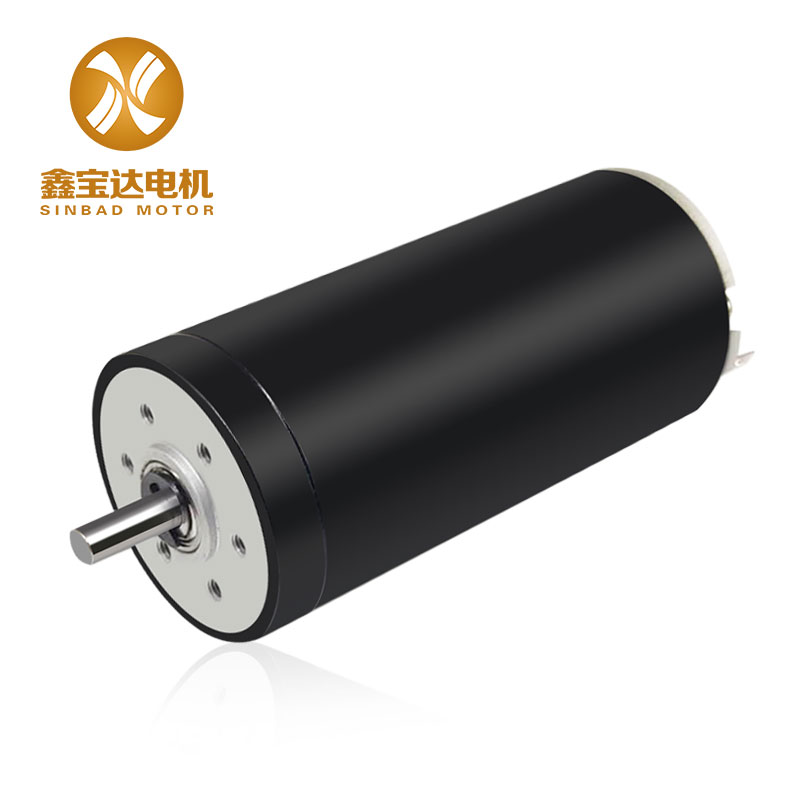

Guangdong Sinbad Motor (Co., Ltd.) was established in June 2011. It is a high-tech enterprise specializing in the research and development, production and sales of coreless motors. Accurate market positioning, professional R&D team, high-quality products and services have enabled the company to develop rapidly since its establishment. Welcome to consult:ziana@sinbad-motor.com

Writer:Ziana

Post time: May-17-2024