Oil-impregnated bearings and ball bearings are two common bearing types that find a wide range of applications in industry and machinery. Although they are both used to support and reduce friction and wear of rotating parts in mechanical devices, they have obvious differences in structure, working principle and application.

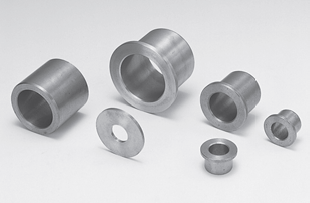

First, let’s take a look at the characteristics and working principle of oil-impregnated bearings. Oil-impregnated bearing is a kind of friction bearing, which usually consists of inner ring, outer ring and rolling elements. The inside of the bearing is filled with lubricating oil or grease. When the bearing rotates, the lubricating oil or grease will form a lubricating film to reduce friction and wear. The advantage of oil-impregnated bearings is that they can withstand larger loads and impacts, and have better wear resistance and load-bearing capacity. Therefore, oil-impregnated bearings are often used in low-speed, high-torque applications such as wind turbines, conveyor belt drives, etc.

A ball bearing is a rolling bearing, which consists of an inner ring, an outer ring, rolling elements (usually balls) and a cage. Ball bearings reduce friction and wear through rolling balls, thereby improving the rotation efficiency and life of the bearing. The advantages of ball bearings are that they provide high rotational accuracy and stability, with low frictional resistance and high rotational speeds. Therefore, ball bearings are often used in high-speed, low-torque applications such as power tools, household appliances, etc.

Structurally, there are also obvious differences between oil-impregnated bearings and ball bearings. Oil-impregnated bearings usually consist of inner rings, outer rings and rolling elements, while ball bearings mostly consist of inner rings, outer rings, rolling elements (balls) and cages. This structural difference leads to their different characteristics in terms of load-bearing capacity, rotation accuracy and applicable speed.

In addition, there are differences in the lubrication methods between oil-impregnated bearings and ball bearings. Oil-containing bearings require lubricating oil or grease to be filled inside the bearing to form a lubricating film to reduce friction and wear; while ball bearings reduce friction through rolling balls and usually only require a small amount of lubricating oil or grease.

In general, there are obvious differences between oil-impregnated bearings and ball bearings in terms of structure, working principle and application. In practical applications, selecting the appropriate bearing type based on specific working conditions and requirements is critical to the performance and life of the mechanical device. Therefore, when designing and selecting bearings, the type and characteristics of the bearings need to be fully considered to ensure that the mechanical device can operate stably and reliably under various working conditions.

Writer: Sharon

Post time: May-08-2024