The design of coreless motors in electronic prostheses is reflected in many aspects, including power system, control system, structural design, energy supply and safety design. Below I will introduce these aspects in detail to better understand the design of coreless motors in electronic prostheses.

1. Power system: The design of the coreless motor needs to consider the power output requirements to ensure the normal movement of the prosthesis. DC motors or stepper motors are usually used, and these motors need to have high speed and torque to meet the movement needs of prosthetic limbs in different situations. Parameters such as motor power, efficiency, response speed and load capacity need to be considered during design to ensure that the motor can provide sufficient power output.

2. Control system: The coreless motor needs to match the control system of the prosthesis to achieve precise motion control. The control system usually uses a microprocessor or embedded system to obtain information about the prosthetic limb and the external environment through sensors, and then accurately controls the motor to achieve various action modes and strength adjustments. Control algorithms, sensor selection, data acquisition and processing need to be considered during design to ensure that the motor can achieve precise motion control.

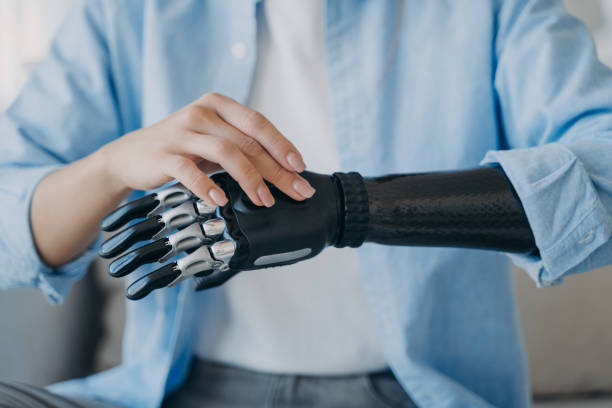

3. Structural design: The coreless motor needs to match the structure of the prosthesis to ensure its stability and comfort. Lightweight materials, such as carbon fiber composite materials, are usually used to reduce the weight of prostheses while ensuring sufficient strength and stiffness. When designing, the installation position, connection method, transmission structure, and waterproof and dustproof design of the motor need to be considered to ensure that the motor can closely cooperate with the prosthetic structure while ensuring comfort and stability.

4. Energy supply: The coreless motor requires a stable energy supply to ensure the continuous operation of the prosthesis. Lithium batteries or rechargeable batteries are usually used as energy supply. These batteries need to have high energy density and stable output voltage to meet the working needs of the motor. Battery capacity, charge and discharge management, battery life and charging time need to be considered during design to ensure that the motor can obtain a stable energy supply.

5. Safety design: Coreless motors need to have good safety design to avoid instability or damage to the prosthesis due to motor failure or accidents. Multiple safety protection measures are usually adopted, such as overload protection, overheating protection and short-circuit protection, to ensure that the motor can work safely and reliably under various circumstances. When designing, it is necessary to consider the selection of safety protection devices, trigger conditions, response speed and reliability to ensure that the motor can maintain safe operation under any circumstances.

To sum up, the design of coreless motors in electronic prostheses is reflected in many aspects such as power system, control system, structural design, energy supply and safety design. The design of these aspects needs to comprehensively consider knowledge from multiple fields such as electronic technology, mechanical engineering, materials science and biomedical engineering to ensure that electronic prostheses can have good performance and comfort and provide better rehabilitation and life assistance for disabled people .

Writer : Sharon

Post time: Sep-05-2024