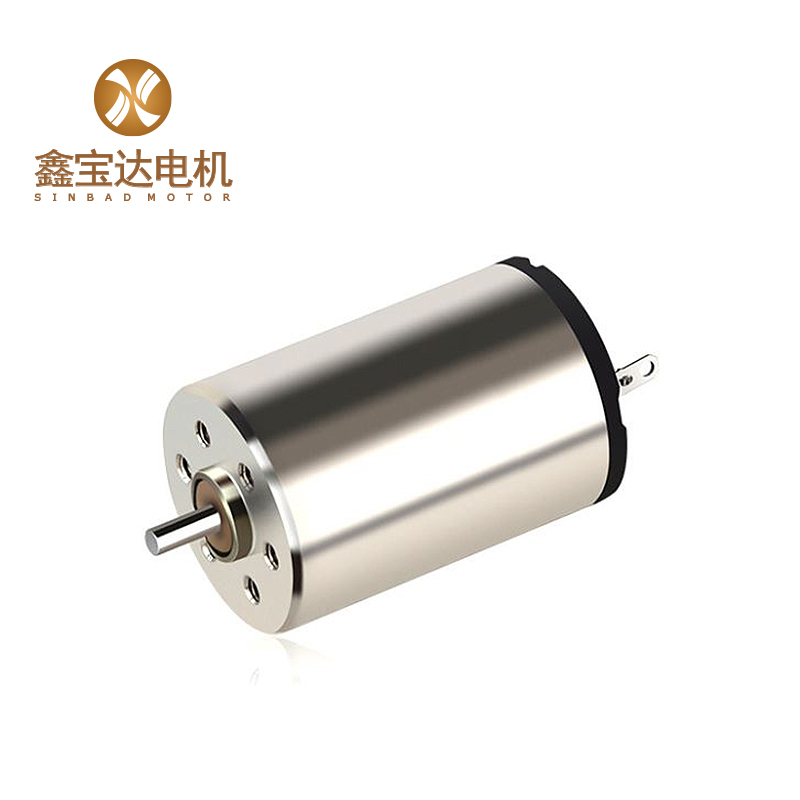

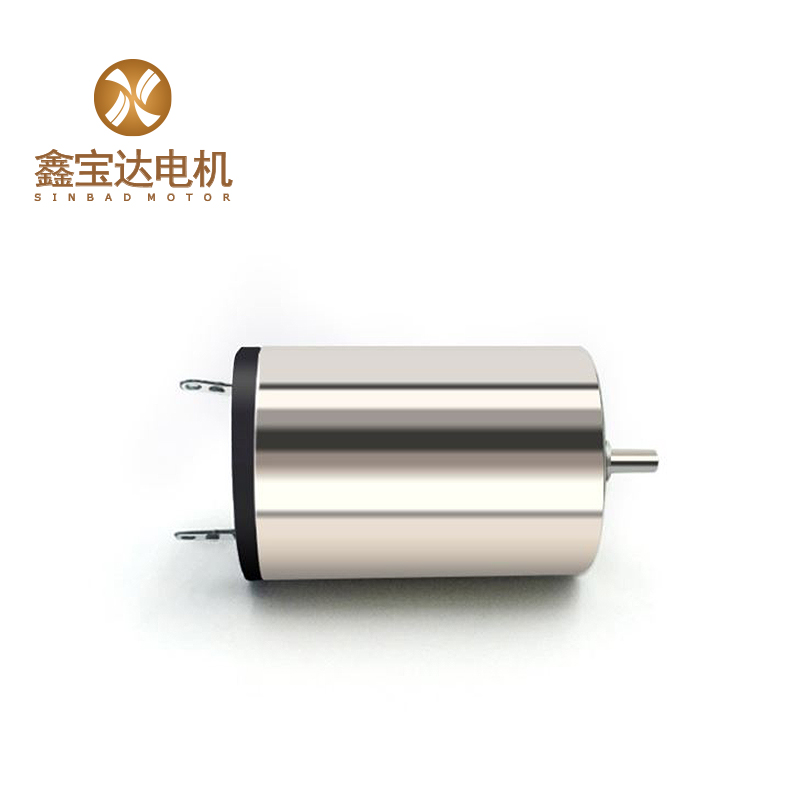

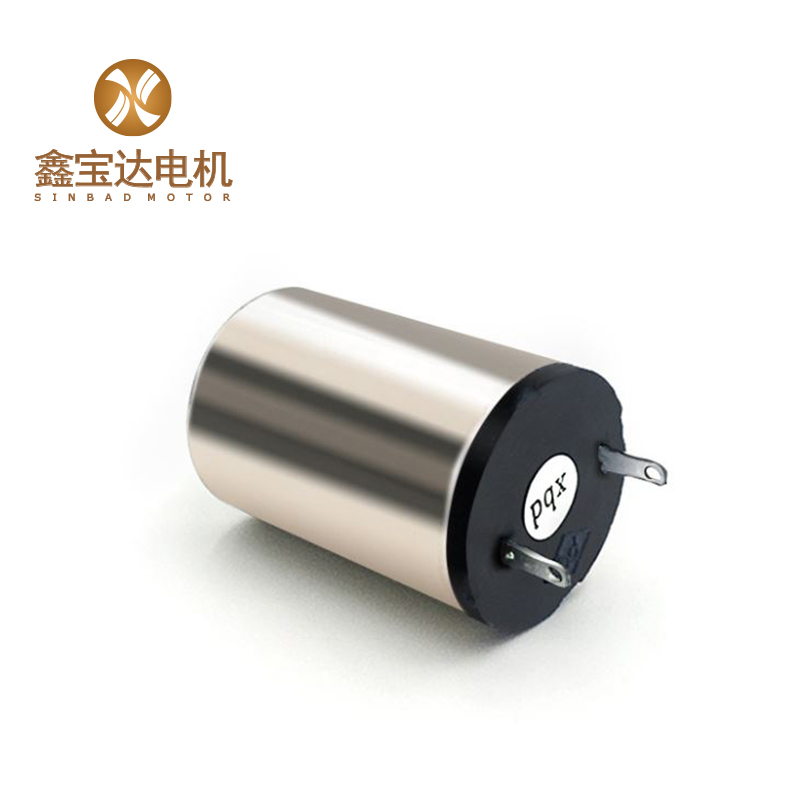

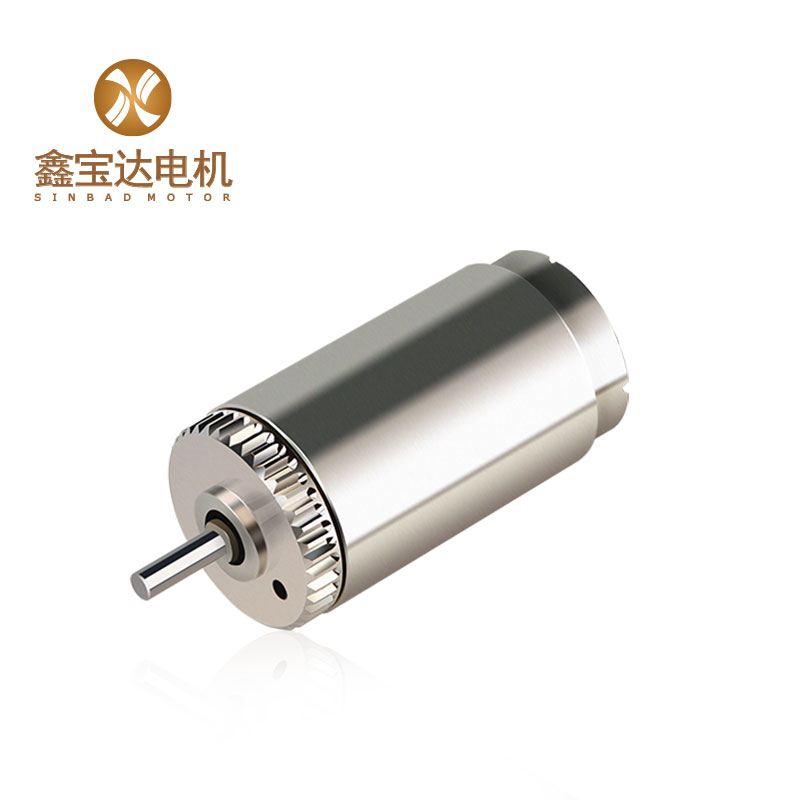

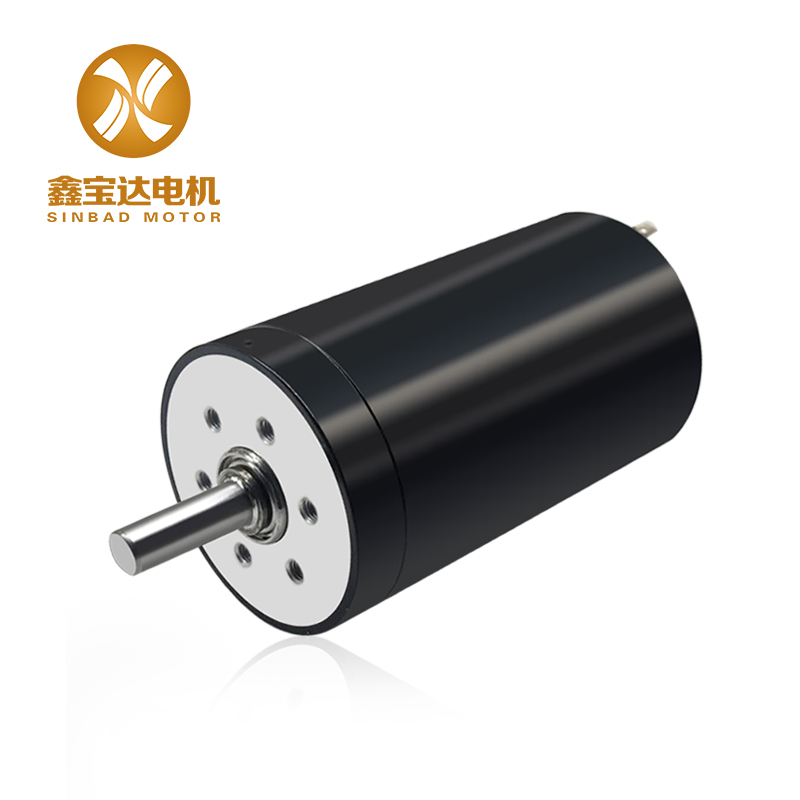

XBD-1928 Precious Metal Brushed DC Motor

Product Introduction

The XBD-1928 Precious Metal Brushed DC motor is a high-performance motor designed for use in a wide range of industrial and automotive applications. This motor features precious metal brushes that offer excellent contact resistance, resulting in increased power output and higher efficiency compared to other motors in its class. The motor is designed with a compact and lightweight construction that makes it easy to integrate into applications where space is limited. It is also highly durable and resistant to wear and tear, ensuring reliable operation even in harsh environments. The motor can be mounted in a variety of orientations, making it ideal for a wide range of applications. Additionally, it operates with low noise and vibration, making it suitable for precision applications where noise and vibration are a concern. The 1928 Precious Metal Brushed DC motor is an excellent choice for anyone seeking a powerful and efficient motor for use in demanding industrial and automotive applications.

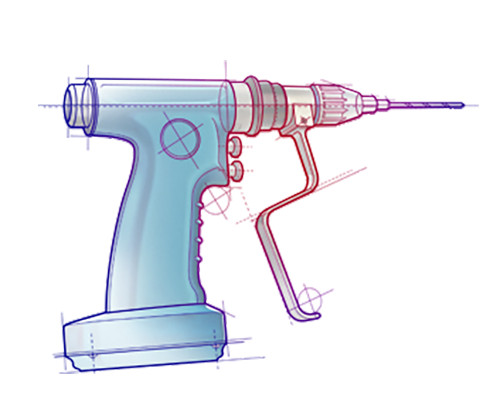

Application

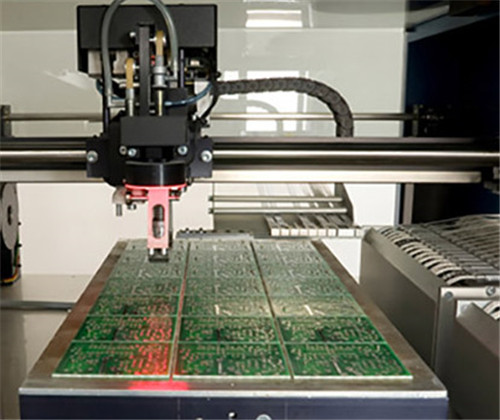

Sinbad coreless motor have a wide range of application such as robots, drones, medical equipment, automobiles, information and communications, power tools, beauty equipment, precision instruments and military industry.

Advantage

The XBD-1928 Precious Metal Brushed DC motor offers several advantages over other motors in its class:

1. Increased power output and efficiency: The precious metal brushes used in the motor provide excellent contact resistance, resulting in higher power output and improved efficiency.

2. Compact and lightweight design: The motor's compact and lightweight construction makes it easy to integrate into applications where space is limited.

3. Durability: The motor is highly durable and resistant to wear and tear, ensuring reliable operation even in harsh environments.

4. Versatility: The motor can be mounted in a variety of orientations, making it ideal for a wide range of applications.

5. Low noise and vibration: The motor operates with low noise and vibration, making it suitable for precision applications where noise and vibration are a concern.

Overall, the 1928 Precious Metal Brushed DC motor provides a powerful and efficient motor solution for demanding industrial and automotive applications.

Parameter

| Motor model 1928 | |||||

| Brush material precious metal | |||||

| At nominal | |||||

| Nominal voltage | V |

6 |

9 |

12 |

24 |

| Nominal speed | rpm |

7071 |

8064 |

9129 |

5397 |

| Nominal current | A |

0.36 |

0.37 |

0.34 |

0.09 |

| Nominal torque | mNm |

2.22 |

3.02 |

3.40 |

2.68 |

|

Free load |

|||||

| No-load speed | rpm |

7900 |

9010 |

10200 |

6030 |

| No-load current | mA |

45.0 |

46.5 |

35.2 |

15.0 |

|

At max efficiency |

|||||

| Max efficiency | % |

77.0 |

77.4 |

79.4 |

72.9 |

| Speed | rpm |

7100 |

8019 |

9180 |

5306 |

| Current | A |

0.341 |

0.381 |

0.327 |

0.097 |

| Torque | mNm |

2.1 |

3.2 |

3.2 |

3.1 |

|

At max output power |

|||||

| Max output power | W |

4.4 |

6.8 |

8.6 |

4.0 |

| Speed | rpm |

3950 |

4505 |

5100 |

3015 |

| Current | A |

1.5 |

1.6 |

1.5 |

0.4 |

| Torque | mNm |

10.6 |

14.4 |

16.2 |

12.7 |

|

At stall |

|||||

| Stall current | A |

3.00 |

3.10 |

2.95 |

0.70 |

| Stall torque | mNm |

21.1 |

28.7 |

32.4 |

25.5 |

|

Motor constants |

|||||

| Terminal resistance | Ω |

2.00 |

2.90 |

4.07 |

34.29 |

| Terminal inductance | mH |

0.153 |

0.312 |

0.492 |

3.160 |

| Torque constant | mNm/A |

7.04 |

9.26 |

10.97 |

36.40 |

| Speed constant | rpm/V |

1316.7 |

1001.1 |

850.0 |

251.3 |

| Speed/Torque constant | rpm/mNm |

374.2 |

313.7 |

315.2 |

236.7 |

| Mechanical time constant | ms |

11.76 |

9.86 |

9.08 |

7.75 |

| Rotor inertia | g·cm² |

3.00 |

3.02 |

2.75 |

3.13 |

| Number of pole pairs 1 | |||||

| Number of phase 5 | |||||

| Weight of motor | g | 40 | |||

| Typical noise level | dB | ≤38 | |||

Samples

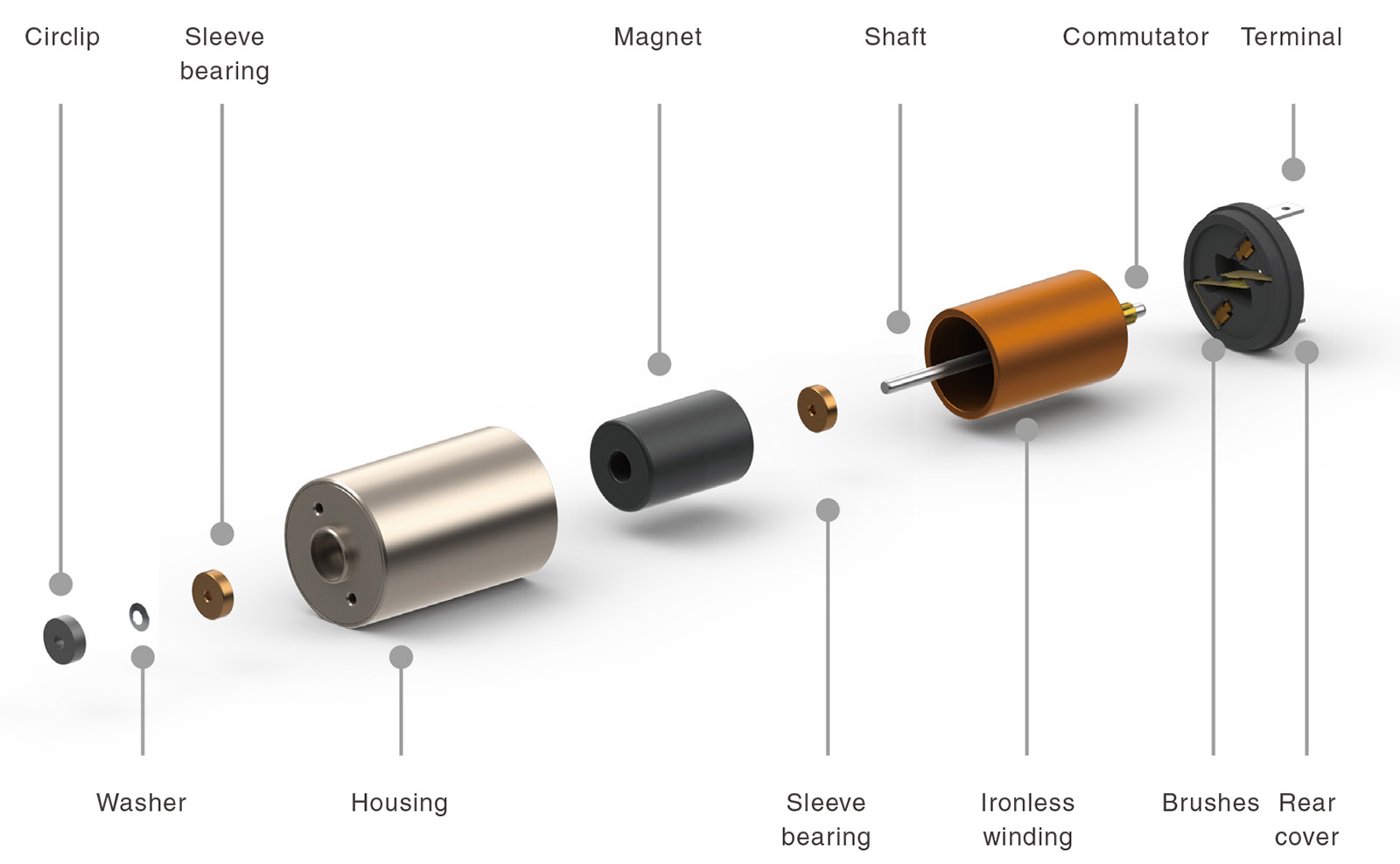

Structures

FAQ

A: Yes. We are a manufacturer specializing in Coreless DC Motor since 2011.

A: We have QC team comply with TQM, each step is in compliance to the standards.

A: Normally, MOQ=100pcs. But small batch 3-5 piece is accepted.

A: Sample is available for you. please contact us for details. Once we charge you sample fee, please feel easy, it will be refund when you place mass order.

A: send us inquiry → receive our quotation → negotiate details → confirm the sample → sign contract/deposit → mass production → cargo ready → balance/delivery → further cooperation.

A: Delivery time depends on the quantity you order. usually it takes 30~45 calendar days.

A: We accept T/T in advance. Also we have different bank account for receiving money, like US dollors or RMB etc.

A: We accept payment by T/T, PayPal, the other payment ways also could be accepted,Please contact us before you pay by the other payment ways. Also 30-50% deposit is available, the balance money should be paid before shipping.

In today's fast-paced world, almost everything from shipping to manufacturing relies heavily on motor-driven mechanical systems. Electric motors are such an integral part of our everyday lives that they are so ubiquitous that we often forget to take proper precautions when using them. However, when we ignore the most basic motor usage precautions, there is always the possibility of injury, property damage, or worse. In this article, we'll discuss some of the most critical motor usage considerations that everyone should follow.

First, it's important to know what type of motor you're using. Different types of motors have unique specifications and the manufacturer's instructions must be followed to avoid any accidents. Electric motors can run on electricity, gasoline or diesel, each with different requirements and associated hazards. For example, electric motors require special attention to avoid electric shock, while internal combustion engines present a risk of fire and explosion.

One of the most important motor usage precautions is to make sure the motor is adequately secured in place. Electric motors are powerful mechanical devices that vibrate and generate great force when in operation. Improper installation or loose fittings can cause the motor to vibrate uncontrollably, causing property damage, equipment failure, and even personal injury. Always make sure the motor is firmly in place and check for any loose screws, bolts or fittings before starting the motor.

Another important motor usage precaution is to keep the motor and its surroundings clean and free of debris. Motors heat up, and the buildup of dust and debris can lead to overheating and motor failure. Also, keeping the area around the motor clean and clear of obstructions can prevent accidental contact with moving parts that could cause serious injury. Always clean the motor and surrounding area regularly and ensure that it is well ventilated for proper air circulation.

Regular maintenance is another important motor usage consideration that should not be overlooked. Electric motors are mechanical devices that require regular maintenance to keep them in good working order. Failure to maintain a motor can cause it to malfunction or even lead to a dangerous situation. Regular maintenance tasks include cleaning, lubricating and inspecting the internal parts of the motor. Always consult the manufacturer's instructions for recommended maintenance plans and procedures.