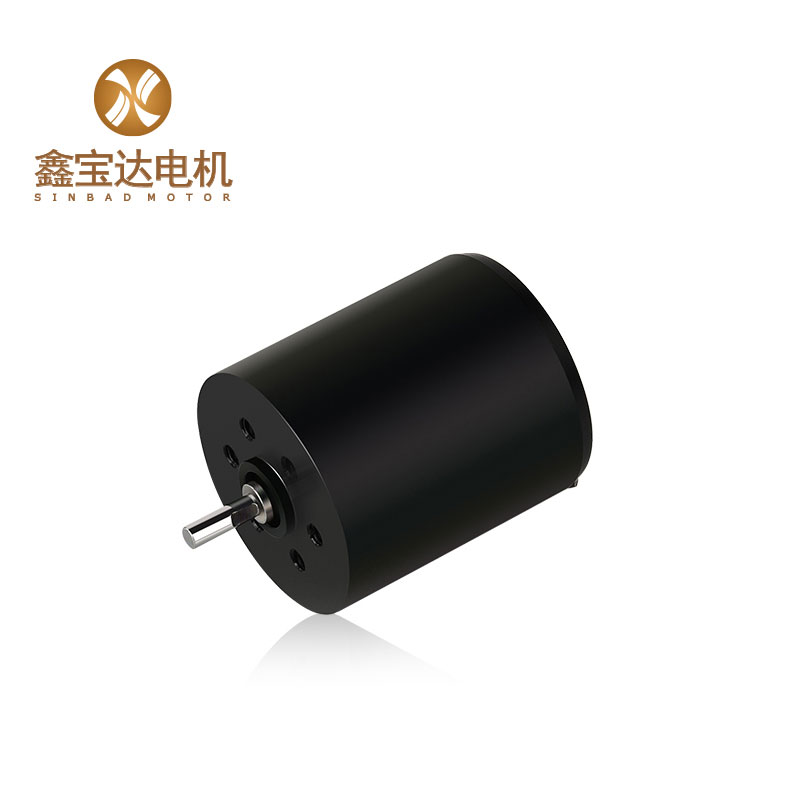

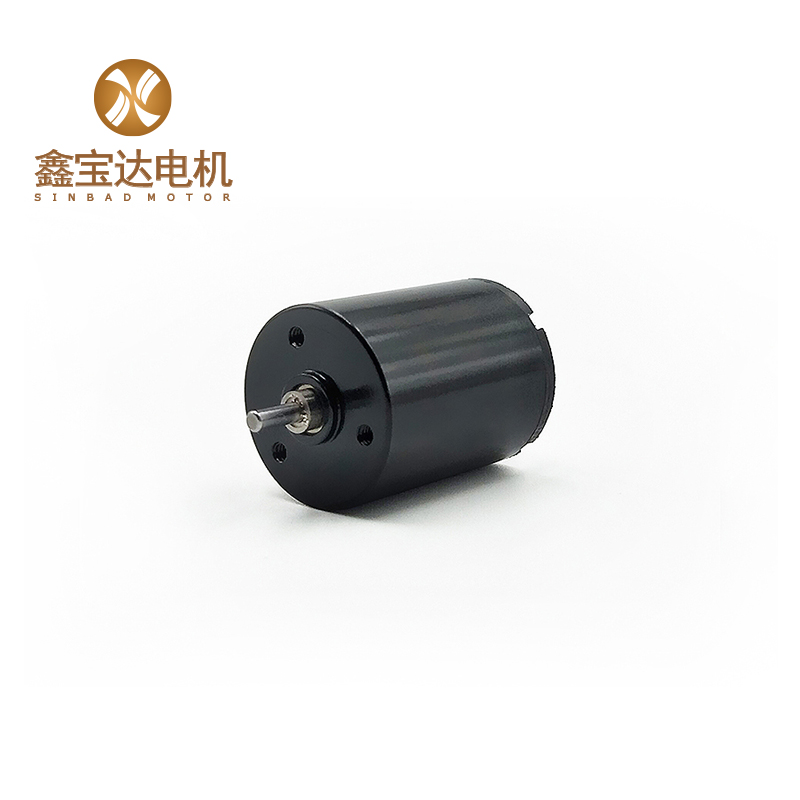

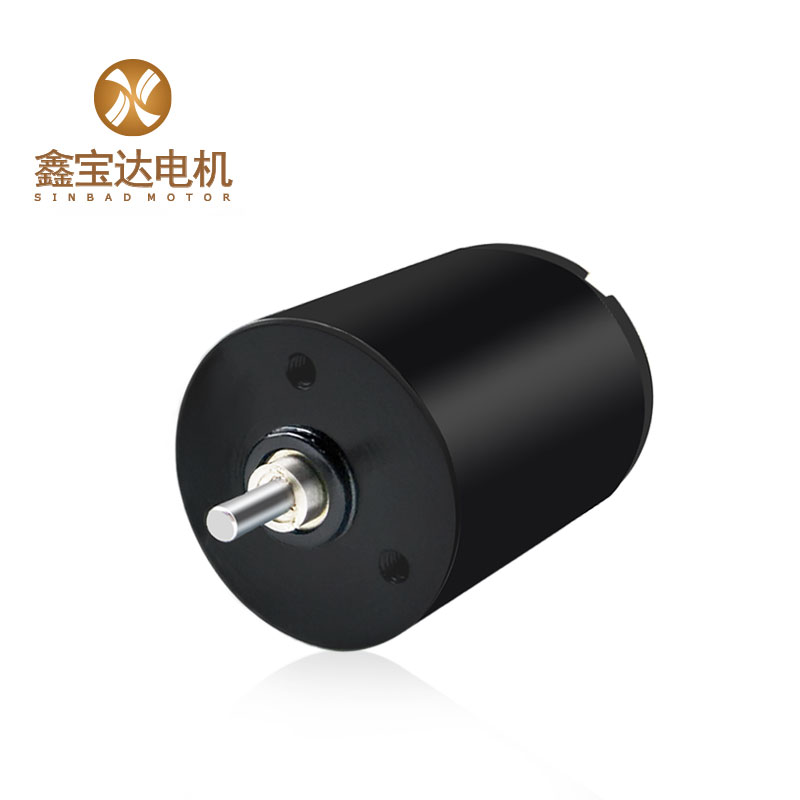

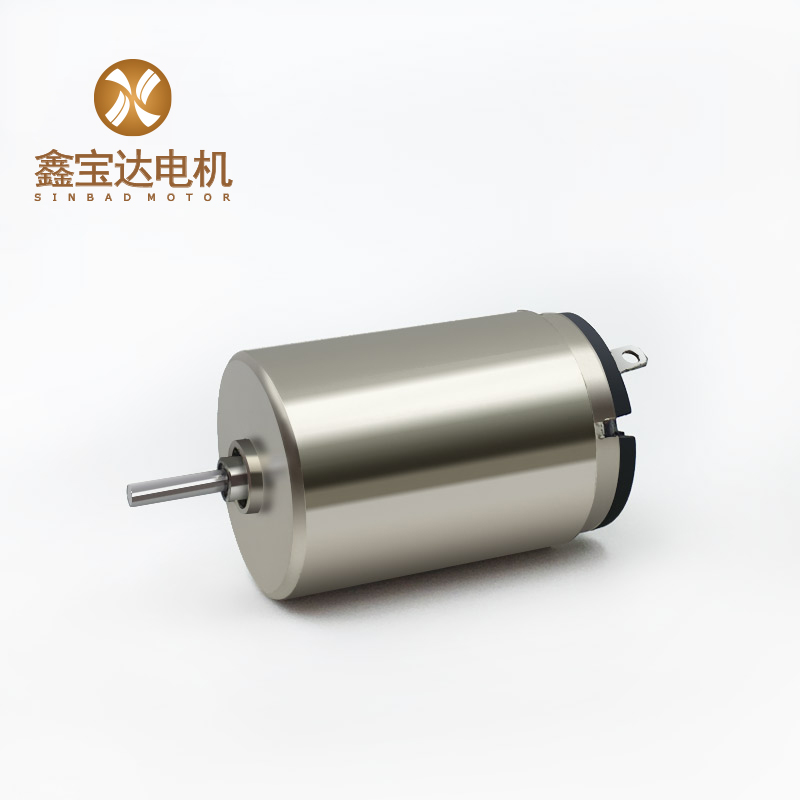

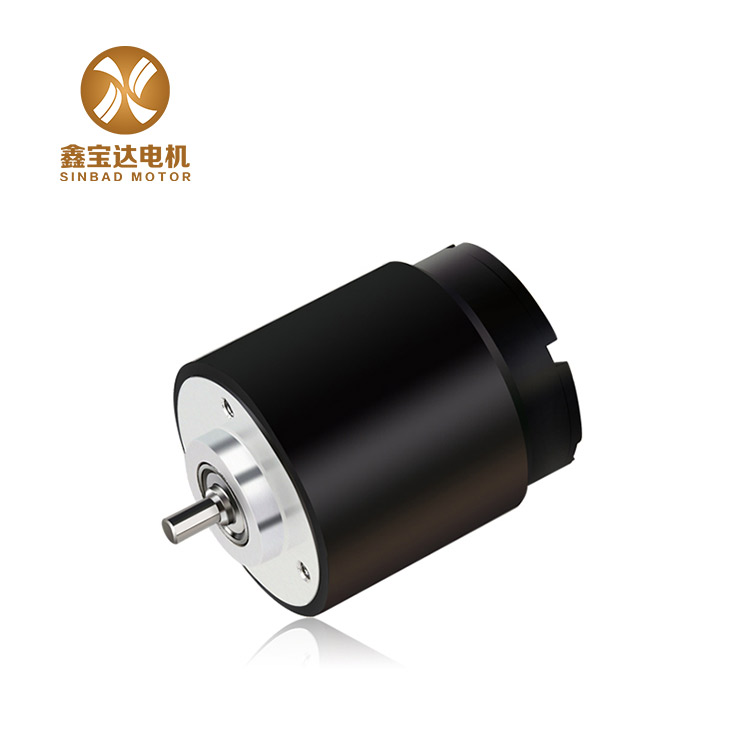

XBD-2225 Precious Metal Brushed DC Motor

Product Introduction

The XBD-2225 Precious Metal Brushed DC motor is a high-performance motor that features precious metal brushes, making it especially efficient and reliable. Its compact and lightweight design make it easy to incorporate into a variety of applications, while its durable construction ensures that it can withstand frequent use and harsh environments. Additionally, the motor operates with low noise and vibration, making it suitable for use in a wide range of settings where noise is a concern. Finally, the motor is versatile and can be mounted in different orientations, making it adaptable to various applications. Overall, the 2225 Precious Metal Brushed DC motor provides superior performance, reliability, and flexibility for a variety of industrial and commercial applications.

Application

Sinbad coreless motor have a wide range of application such as robots, drones, medical equipment, automobiles, information and communications, power tools, beauty equipment, precision instruments and military industry.

Advantage

The XBD-2225 Precious Metal Brushed DC motor offers the following advantages:

1. High-performance: The motor uses precious metal brushes, which results in higher power output and improved efficiency, making it ideal for applications that require high performance.

2. Compact and lightweight: The motor's compact and lightweight design makes it easy to integrate into a variety of applications where space is limited.

3. Durable: The motor is highly durable and can withstand harsh environments and frequent use, making it reliable and cost-effective.

4. Low noise and vibration: The motor operates with low noise and vibration, making it suitable for use in applications where noise and vibration are a concern.

5. Versatile: The motor can be mounted in a variety of orientations and is suitable for a wide range of applications.

Overall, the Precious Metal Brushed DC motor offers high performance, durability, reliability, versatility, and low noise and vibration, making it a top choice for industrial and commercial applications.

Parameter

| Motor model 2225 | |||||

| Brush material precious metal | |||||

| At nominal | |||||

| Nominal voltage | V |

3 |

6 |

12 |

24 |

| Nominal speed | rpm |

6764 |

6806 |

6889 |

6474 |

| Nominal current | A |

0.70 |

0.50 |

0.32 |

0.12 |

| Nominal torque | mNm |

2.35 |

3.28 |

4.13 |

3.44 |

|

Free load |

|||||

| No-load speed | rpm |

7600 |

8200 |

8300 |

7800 |

| No-load current | mA |

70 |

30 |

20 |

6 |

|

At max efficiency |

|||||

| Max efficiency | % |

79.2 |

80.4 |

80.0 |

82.3 |

| Speed | rpm |

6840 |

7421 |

7512 |

7137 |

| Current | A |

0.643 |

0.295 |

0.189 |

0.065 |

| Torque | mNm |

2.1 |

1.8 |

2.3 |

1.7 |

|

At max output power |

|||||

| Max output power | W |

4.2 |

4.1 |

5.3 |

4.1 |

| Speed | rpm |

3800 |

4100 |

4150 |

3900 |

| Current | A |

2.9 |

1.4 |

0.9 |

0.4 |

| Torque | mNm |

10.7 |

9.6 |

12.2 |

10.1 |

|

At stall |

|||||

| Stall current | A |

5.80 |

2.82 |

1.80 |

0.70 |

| Stall torque | mNm |

21.3 |

19.3 |

24.3 |

20.2 |

|

Motor constants |

|||||

| Terminal resistance | Ω |

0.52 |

2.13 |

6.67 |

34.29 |

| Terminal inductance | mH |

0.013 |

0.045 |

0.240 |

0.800 |

| Torque constant | mNm/A |

3.72 |

6.91 |

13.65 |

29.13 |

| Speed constant | rpm/V |

2533.3 |

1366.7 |

691.7 |

325.0 |

| Speed/Torque constant | rpm/mNm |

356.2 |

425.2 |

341.5 |

385.8 |

| Mechanical time constant | ms |

9.93 |

12.30 |

10.61 |

11.84 |

| Rotor inertia | g·cm² |

2.66 |

2.76 |

2.97 |

2.93 |

| Number of pole pairs 1 | |||||

| Number of phase 5 | |||||

| Weight of motor | g | 48 | |||

| Typical noise level | dB | ≤38 | |||

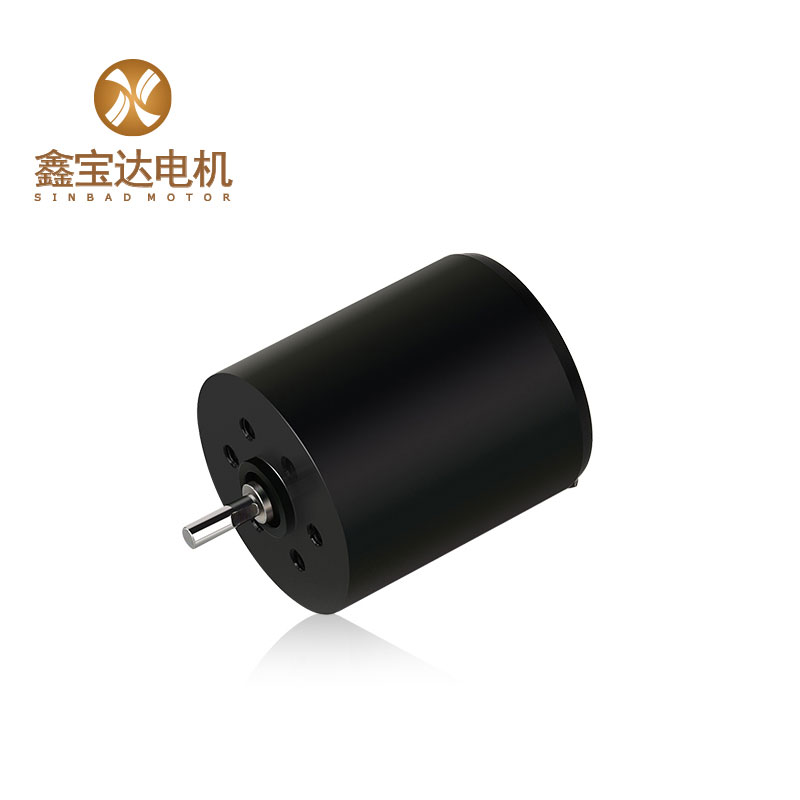

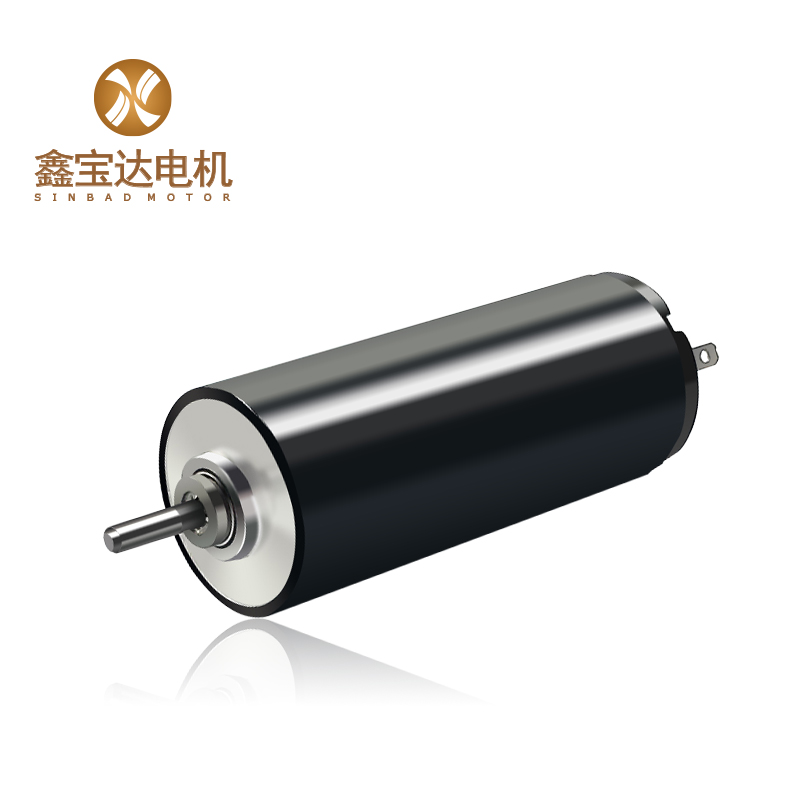

Samples

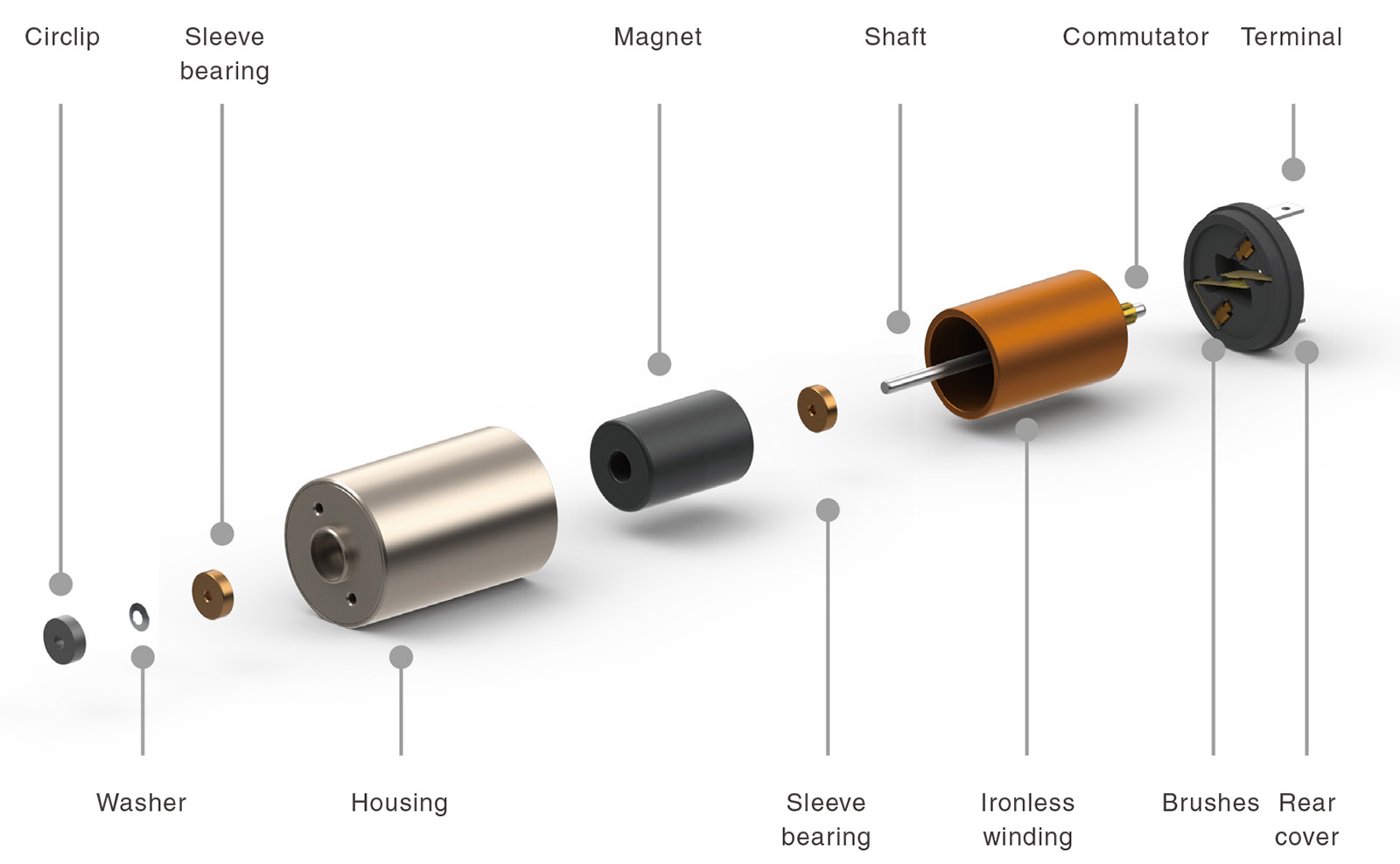

Structures

FAQ

A: Yes. We are a manufacturer specializing in Coreless DC Motor since 2011.

A: We have QC team comply with TQM, each step is in compliance to the standards.

A: Normally, MOQ=100pcs. But small batch 3-5 piece is accepted.

A: Sample is available for you. please contact us for details. Once we charge you sample fee, please feel easy, it will be refund when you place mass order.

A: send us inquiry → receive our quotation → negotiate details → confirm the sample → sign contract/deposit → mass production → cargo ready → balance/delivery → further cooperation.

A: Delivery time depends on the quantity you order. usually it takes 30~45 calendar days.

A: We accept T/T in advance. Also we have different bank account for receiving money, like US dollors or RMB etc.

A: We accept payment by T/T, PayPal, the other payment ways also could be accepted,Please contact us before you pay by the other payment ways. Also 30-50% deposit is available, the balance money should be paid before shipping.

Choosing the right motor can be a daunting task. Not all motors are created equal, and choosing the correct one can make a big difference in a machine's performance. It is important to consider various factors when selecting a motor to ensure it is right for your needs.

The first thing to consider when choosing a motor is the type of machine you are going to build. Different machines require different types of motors. For example, a machine that requires high torque at low speed requires a different type of motor than one that requires high speed at low torque. It is important to determine the type of machine you are building and the type of motor that is best suited for the application.

Another important factor to consider when selecting a motor is the power rating. The power rating of a motor determines how much power it can output. If you are building a machine that requires a lot of power, you will need a motor with a high power rating. It is important to choose a motor with the proper power rating to ensure it can handle the load you put on it.

In addition to power rating, it is also important to consider the efficiency of the motor. Inefficient motors waste energy, leading to increased energy costs and reduced performance. Look for motors with high efficiency ratings to ensure you get the most out of your machine.

One thing that is often overlooked when selecting a motor is the operating environment. Motors can be exposed to various environmental factors such as temperature, humidity and dust. It is important to select a motor that is designed to operate in the environment in which it will be used. Motors that are not designed for their specific environment may fail prematurely or not perform as intended.

Another important factor to consider when selecting a motor is the type of control system that will be used. Different motors require different types of control systems, so it is important to choose a motor that is compatible with the control system you will be using. Some motors require more complex control systems than others, so it is important to choose a motor that is compatible with the level of control system you need.

Finally, it is also important to consider cost when selecting a motor. Motors vary widely in price, so it's important to choose one that fits your budget. However, it's also important to remember that the cheapest motor isn't always the best choice. Look for motors that are value for money, rather than simply picking the cheapest option.

Selecting the correct motor is an important decision that can have a significant impact on a machine's performance. By considering factors such as the type of machine you are building, power rating, efficiency, operating environment, control system and cost, you can choose the motor that best suits your needs. Take the time to research and select the best motor for your application and you will be rewarded with a top performing machine.